Tool Tutorial

Link to PDF Tool Tutorial: Letter size straight stitch 2025.pdf

Link to 2025 rev. poster: 24 x 24 straight stitch poster 2025.pdf

TODO: factor out content shared with Industrial Walking Foot

This machine is great for working with long straight items like draperies and bedding using fabric ranging from light to medium weight.

Maximum sewing speed is 5500 stitches per minute!

Warnings

🚫 Do not push or pull material while stitching.

⚠️ Power off the machine before threading, inserting the bobbin, or handling the needle.

⚠️ Keep hair, loose clothing, and fingers away from all moving parts!

See the Safety Section for more information.

Tool Anatomy

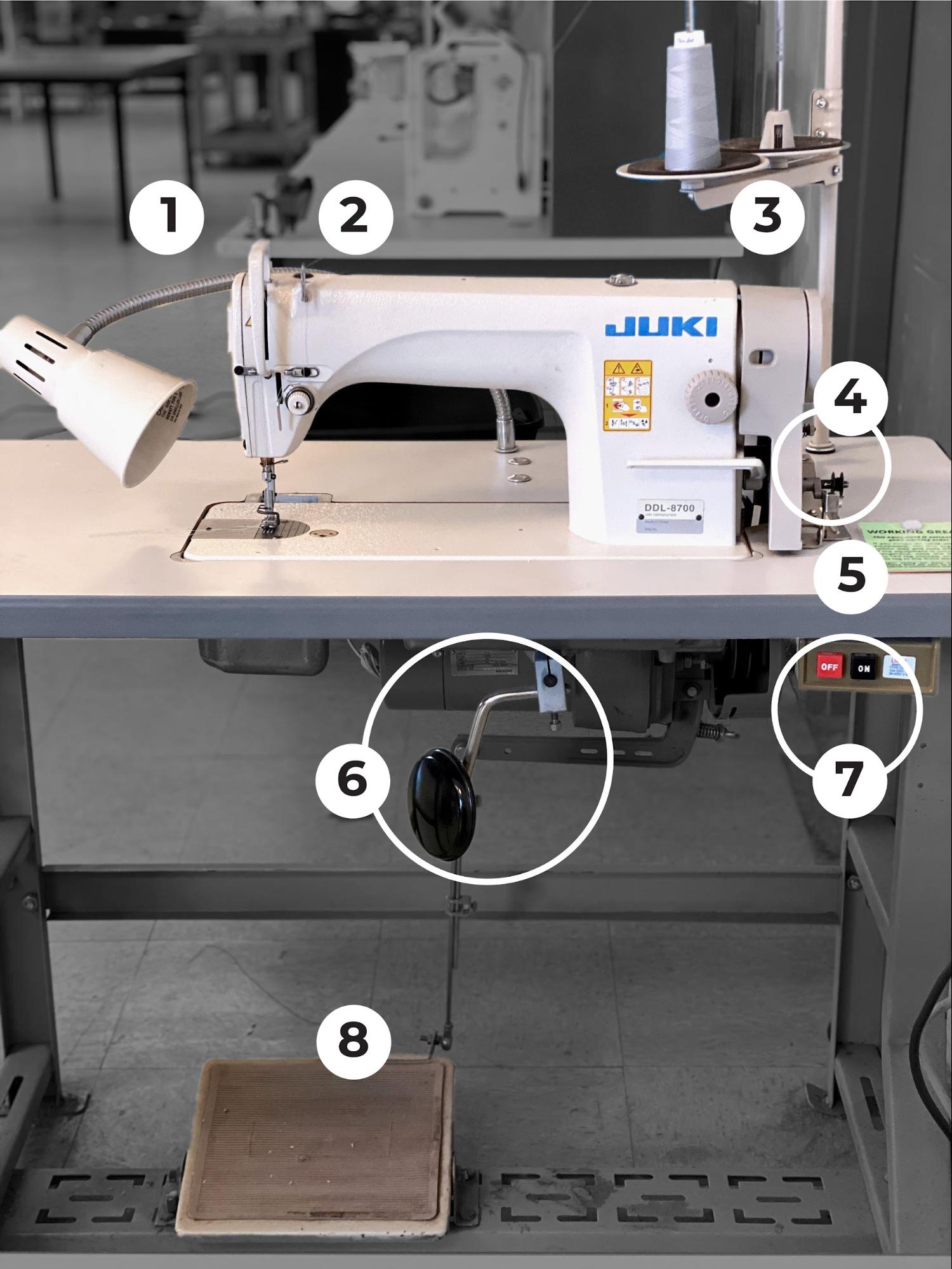

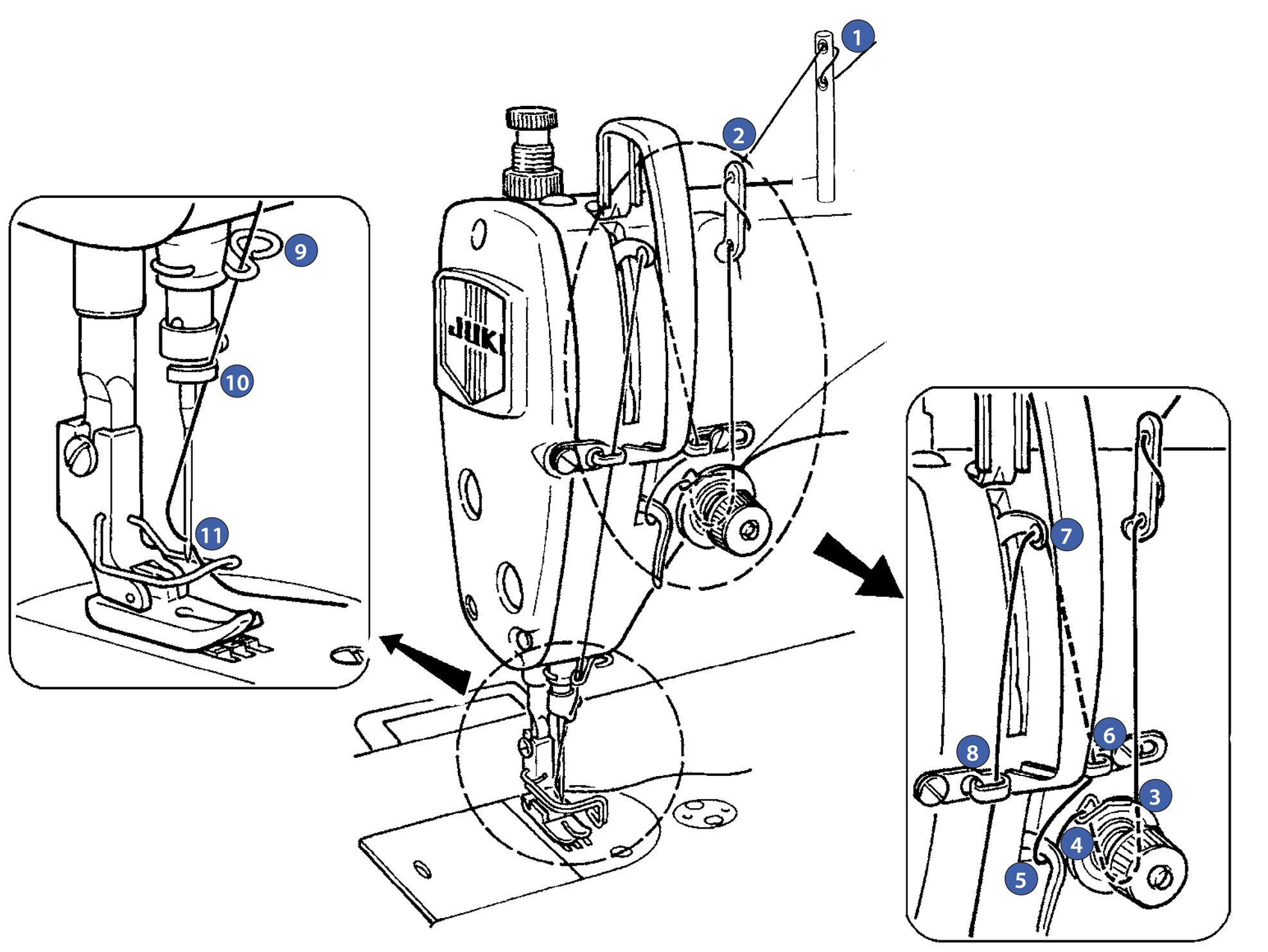

GENERAL LAYOUT

-

Light - For easy viewing

-

Straight Stitch - The Machine

-

Thread Holders - Please Note: The secondary holder is for continual bobbin winding

-

Bobbin Winder

-

Maintenance Tag - Manually tracks the usability status with Green/Yellow/Red cards

-

Knee Presser Foot Lifter - Knee operated lever that lifts the presser foot while sewing

-

On/Off Switch - Main power to the machine

-

Foot Pedal - Controls the speed of the motor

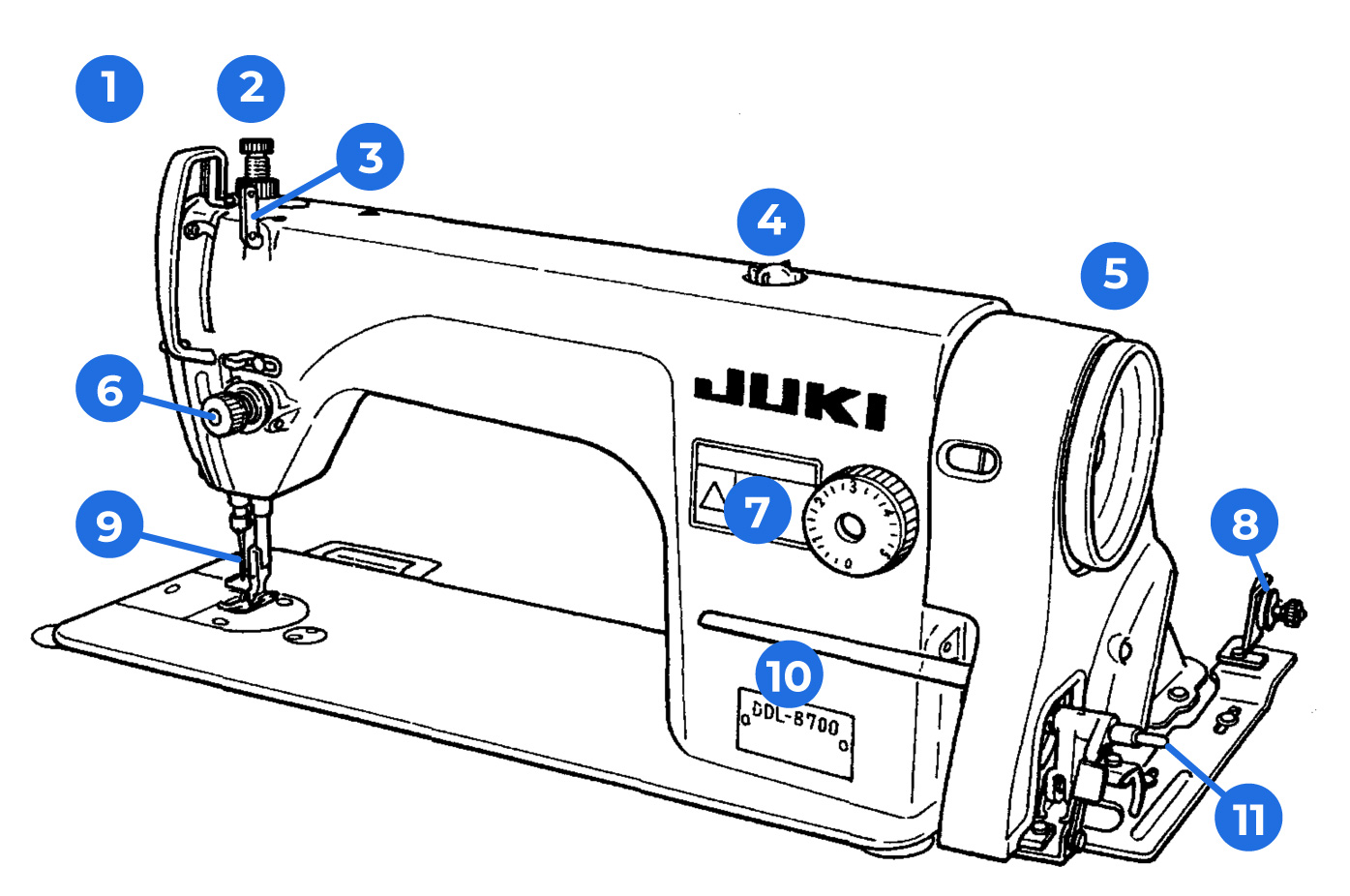

MACHINE ANATOMY

-

Manual Presser Foot Lifter (not seen, around back)

-

Presser Foot Height Adjustment

-

Thread Guide

-

Oil Level Indicator

-

Hand Wheel

-

Thread Tension and Guides

-

Stitch Length Knob

-

Bobbin Winder Tensioner

-

Needle

-

Reverse Lever

-

Bobbin Winder Spindle

Tool Safety

Personal Protective Equipment

-

Safety glasses are recommended.

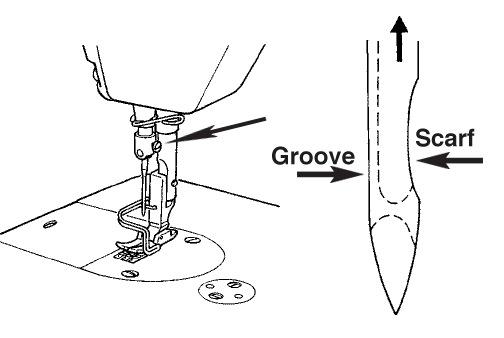

Check the needle condition prior to sewing, be sure it is the correct size for the material being sewn, and it is not bent or chipped.

Never sew over pins, staples or other metal materials, as this may cause the needle to shatter, resulting in bodily harm and severe machine damage.

Always turn the handwheel towards you, (down) never away.

COMMON HAZARDS

The most common hazards are thread jams and broken needles. Watch for binds, jams, and bird nests—stop immediately if they occur.

-

Ensure the needle and thread are removed before winding a bobbin

-

Avoid pulling/pushing fabric, which may misalign and break the needle

The most significant hazard is injury. Always power off and run the machine until the motor drains before handling, adjusting, or threading.

-

Keep fingers 3” away from the needle

-

Power off and drain the motor before:

-

Threading

-

Replacing needles

-

Removing jams

-

-

Tie back hair and scarves

-

Tuck sleeves behind elbows

Prohibited Materials

Thread Jams and needle breakage are critical concerns. Material that is too thick or rigid will lead to needle breakage. Material that is too slick (plasticized or otherwise “finished”) will slide against the presser foot and cause thread jams and/or needle breakage.

Industrial machines will not “step over” pins in the fabric. Hitting one may break the needle and send broken parts into the hook below.

For those reasons, it is important to avoid:

-

Abrasives

-

Paper and cardboard products

-

Pins in the fabric

-

Plastics

-

Rigid Material (non-fabric)

Initial Setup

-

Wipe down the machine and bed to clean up any oil or dust.

-

Check the oil level, see Maintenance.

-

Power on the machine.

-

Wind the bobbin.

-

Power off the machine to insert the bobbin and thread the machine.

-

Thread the machine.

-

Ensure the needle is usable and appropriate for the material and thread.

-

Lower the presser foot and begin operation.

CHECKING NEEDLE SIZE

-

Grab a needle and about 12 inches of the intended thread

-

Thread the needle

-

Hold both ends of the thread, creating a 60 degree slope with one end to see if the needle is able to slide along the slope

-

Reverse the process to see if the needle slides back

If the needle does not freely slide down the thread, the size may be too small. As a general rule, you’ll want the smallest size needle that will slide freely down the thread.

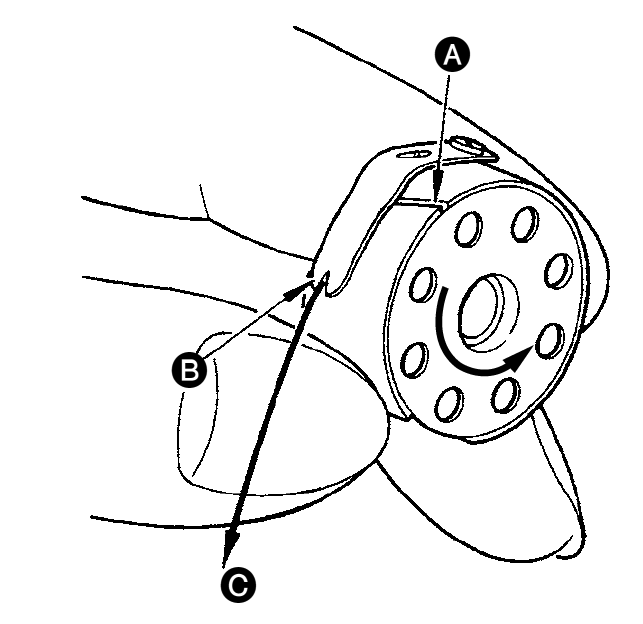

WIND THE BOBBIN

-

Raise the presser foot by winding the handwheel (a) counterclockwise

-

Ensure there is nothing near the needle while filling the bobbin

It does not disengage while winding like a consumer machine

-

Pass the thread through the guide on the tension and between the disks (b).

-

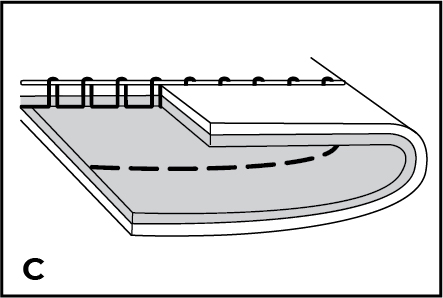

Pass the thread between a hole on the bobbin case ©.

-

Rotate the case 2-3 times to manually wind the thread for traction.

-

Place the bobbin on the spindle, holding onto the tail of loose thread.

-

Gently press the foot pedal to wind the bobbin. It will stop when full.

Please watch this video, which includes details of winding and placing the bobbin in the case.

ATTACH THE BOBBIN CASE

INSERT THE NEEDLE

THREAD THE MACHINE

Thread the machine following the order of (1) through (11) as shown above.

Move the handwheel towards you, never away to get the top thread to take up the bobbin thread.

Operation

-

Setup the machine

-

Raise the presser foot with the knee pedal to load fabric

-

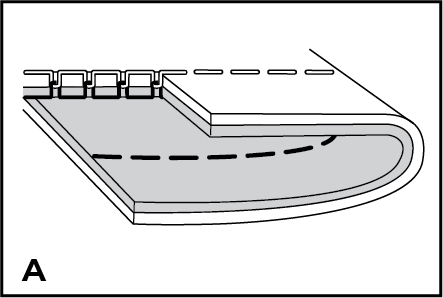

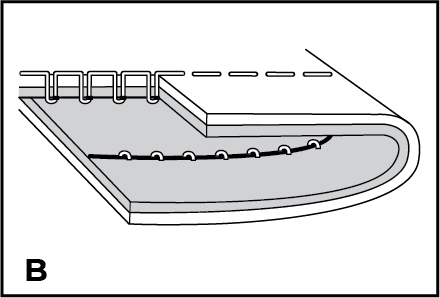

Test by sewing on scrap similar to what you will be sewing

-

Adjust the tension and stitch length

-

Remove test and trim threads

-

Load and align project fabric

-

Back stitch/reverse to keep your stitch from unraveling

-

Sew

-

Cleanup

ADJUST THE TENSION

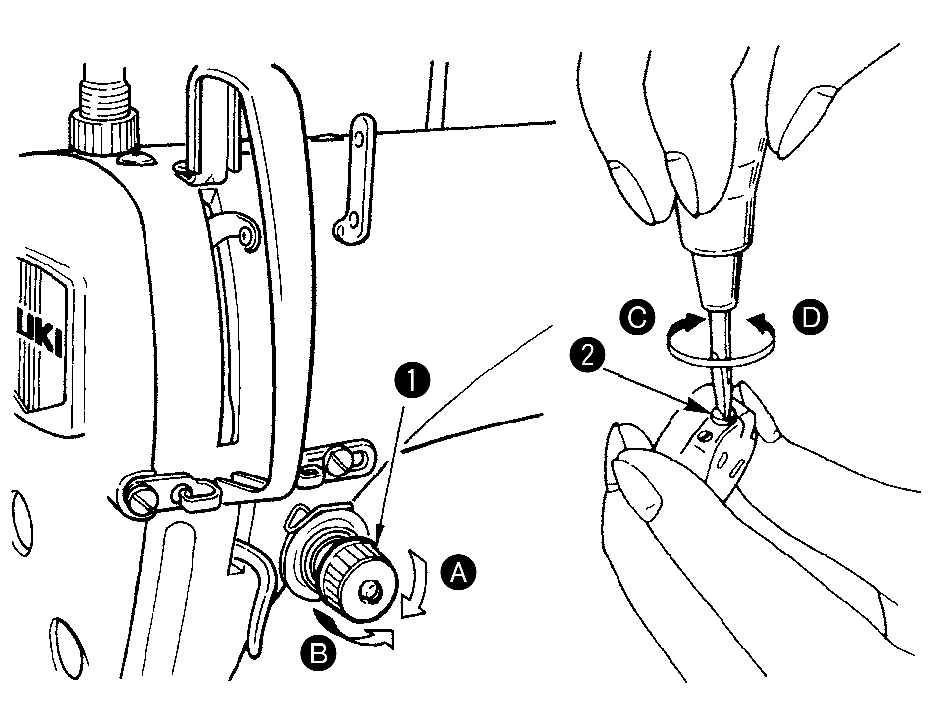

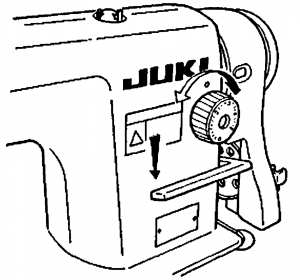

(1) Adjusting the needle thread tension

-

Direction A clockwise - to increase needle thread tension.

-

Direction B counterclockwise - to decrease needle thread tension.

(2) Adjusting the bobbin thread tension

-

Turn tension adjustment screw 2 clockwise (in direction C), to increase bobbin thread tension.

-

Turn tension adjustment screw 2 counterclockwise (in direction D), to decrease bobbin thread tension.

BACKSTITCH & STITCH SIZE

Cleanup

- Power off and drain the machine

- Unthread machine head and spool

- Remove bobbin

- Wipe down, vacuum, and blow out lint and stray clippings

- Sweep up threads, lint, and debris and deposit in waste bins

- Return stray items to drawer under table

MAINTENANCE REQUESTS

Record issues at protohaven.org/maintenance. This notifies our staff and volunteer maintenance crew of any issues.

Troubleshooting

| Common Issues | Possible Causes | Resolutions |

|---|---|---|

| Thread comes out of the needle on the first few stitches | The threads need a longer tail, and needs to be held back, or The take up lever is not at its highest position |

Pull threads to the back when beginning the seam, with the take-up lever in it’s highest position |

| Thread clumps up and fabric won’t feed through | Bent needle, needle inserted incorrectly, machine threaded incorrectly | Be sure it is threaded left to right. Be sure the needle is right for the fabric. |

| Skipped stitches | Bent needle, needle inserted incorrectly, machine threaded incorrectly | Turn off the machine be sure there is no jam near the hook and bobbin casing, then re-thread the machine and bobbin |

Special Setups

For all of the following, please make a Special Setup Arrangement with a Protohaven Staff Member to gain clearance in advance of use. Consider whether you need specialty adjustments as part of an extended project, or if the adjustments or accessories are temporary.

WINDING THE BOBBIN WHILE SEWING

For large projects, a second bobbin can be wound while sewing.

-

A second spool of thread is required.

-

The needle and presser foot remain in place, and sewing can continue.

-

Follow all other instructions in “Bobbin Winding” above

ADJUSTING THE THREAD TAKE UP STROKE

The amount of thread pulled from the spool can be adjusted to allow thicker or thinner materials to sew more precisely. All adjustments must be reverted to the average settings when finished.

SPECIALIZED PRESSER FOOT

Cording foot, Left/Right piping, Zipper foot, Hemmer - User is responsible for purchasing

SPECIALIZED FEED DOGS

The machine is set for average types of fabric, but can be adjusted for very fine fabric or very thick. The feed dogs can be changed out for various weights, but the user is responsible for purchasing these and re-setting the machine completely after use.

Additional Resources

Sewing Gold Channel : (multiple industrial machine videos)

No Comments