Supporting Long Stock

If you are using a long piece of stock on the metal lathe that extends through the headstock and then out into the walkway, make sure that the setup is secure and safe.

Safety

If the workpiece is only supported at the chuck and extends far out behind the headstock, the unsupported part of the workpiece will drop off axis behind the headstock.

Under rotation, the unsupported part of the workpiece will rotate off axis, and will develop a kink where it leaves the back of the head stock. The piece will bend out from the axis of rotation.

A bent workpiece will spin like a helicopter blade behind the headstock of the metal lathe. This is a massive hazard to anyone and anything in the vicinity of the metal lathe.

Always secure long work pieces behind the headstock when using the metal lathe. We want to support the workpiece so it stays centered on the lathe axis.

Securing the Workpiece

To secure a long workpiece when using the metal lathe, you will need:

- a roller stand

- a large c-clamp

- optional: a rag

Secure the workpiece:

- Use a roller stand to support the workpiece so that the workpiece is centered in the headstock, and parallel to the floor.

- Lock the roller stand height.

- Set up the roller stand so that the roller is skew from the workpiece.

- Use a c-clamp to keep the work piece from lifting off the roller stand, with light but positive contact on the top of the workpiece.

Do not preload excessive force on the top of the workpiece.

- Rotate the stand so that the c-clamp keeps the work piece from drifting left or right across the roller, with light but positive contact on both sides of the workpiece.

Do not preload excessive force on the sides of the workpiece.

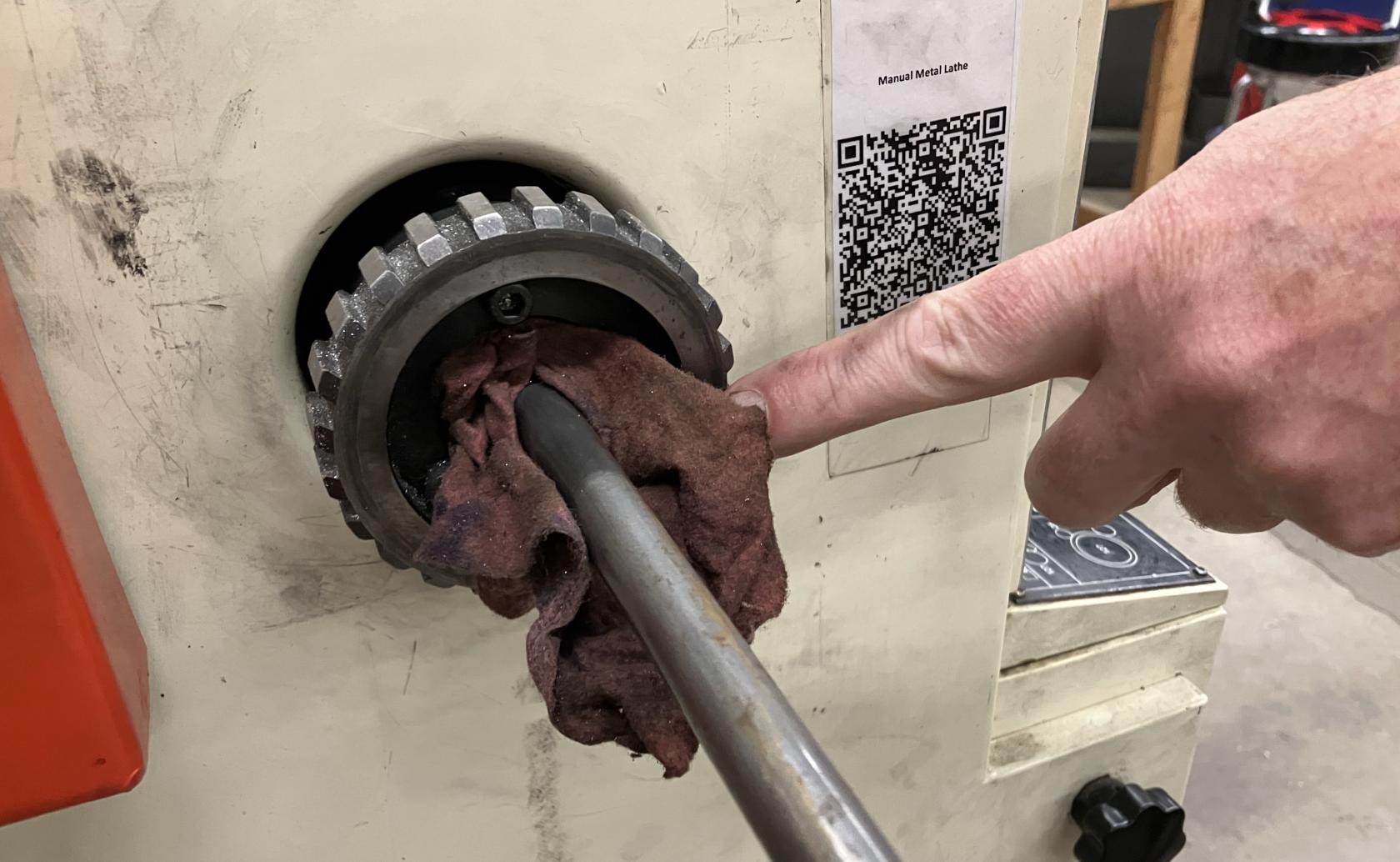

- Optional: lightly place a rag in the back of the headstock around the part to further dampen vibrations.

- Important Last Step: Build a fort: place rolling carts around the area to keep other members from accidentally walking into the workpiece while the metal lathe is in use.

While workpiece is turning, monitor the roller stand to make sure that the workpiece does not walk too far off axis, or there is a danger of the workpiece working out of the c-clamp.

No Comments