Tool Tutorial

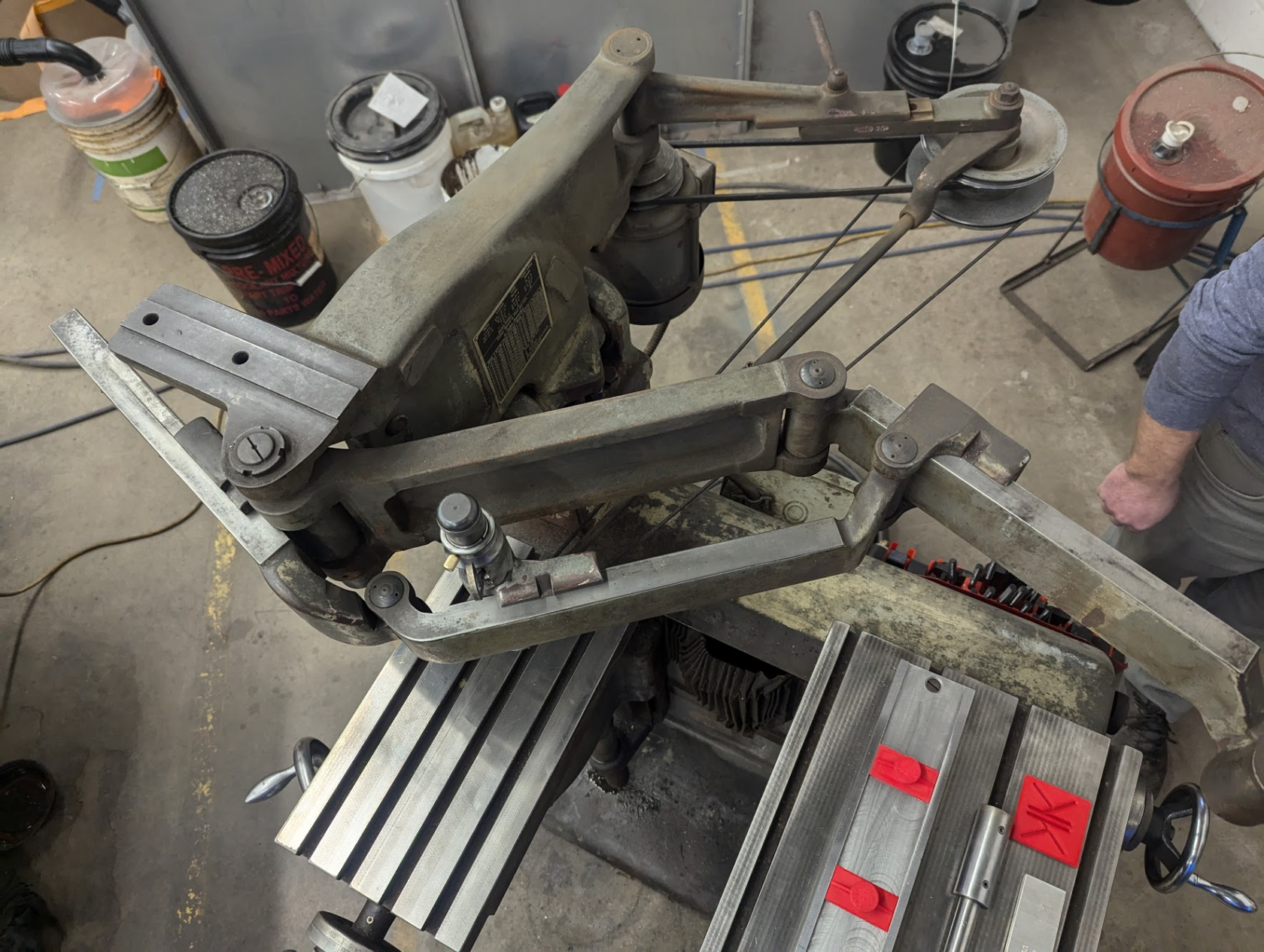

The pantograph is a tool that's especially useful for engraving - maker's marks etc. It uses a template and a 1.5x-10x reduction linkage to achieve very precise motion over a very small space without the aid of a CNC machine.

Basic Info

- This machine has two tables: Pattern table (which holds the pattern) and work table (which holds the piece being engraved).

- All user adjustments require the 3/4" wrench, or the two small collet wrenches for changing end mill bits, located in the drawer of the adjacent desk.

- 3/8" collet is holding a reducer collet that usually contains a collet for 1/8" end mills and engraving bits. A 1/4" collet is in the drawer, if needed. 1/8" bits with a 60º grind are recommended.

Approved Materials

- Aluminum

- Copper

- Brass

- Bronze

- Steel

- Plastic/Delrin

- Please seek advice on any other materials

Safety

- There are spinning elements on this machine and entanglement is a risk

- Glasses are mandatory when operating

- Short sleeve shirt or long sleeves that can be securely rolled up

- No dangling hoodie ties, necklaces, wrist watches, etc.

- Long hair needs to be tied back and secure

2D Mode

Warning: 2D mode only works on FLAT surfaces - make sure your stock material is flat where you are about to engrave.

- Decide on the reduction ratio - how small the result is. All three segments of the arm should be set to the same value indicated on the top of the segment. All 5's for 5:1, all 3's for 3:1 etc.

-

- To change reductions, make sure the stylus is NOT loaded; changing while the stylus is loaded risks breaking the stylus

- Use the 3/4" wrench to loosen the nuts on the back of each of the arm segments, then slide the gauge to the correct number and re-tighten - only a little tightness is needed, don't crank these down.

- Crank the pattern table hand wheel out so that the end of the arm is appropriately located over the top of the pattern table - the two tables must be farther apart for a larger reduction, and closer together for a smaller reduction.

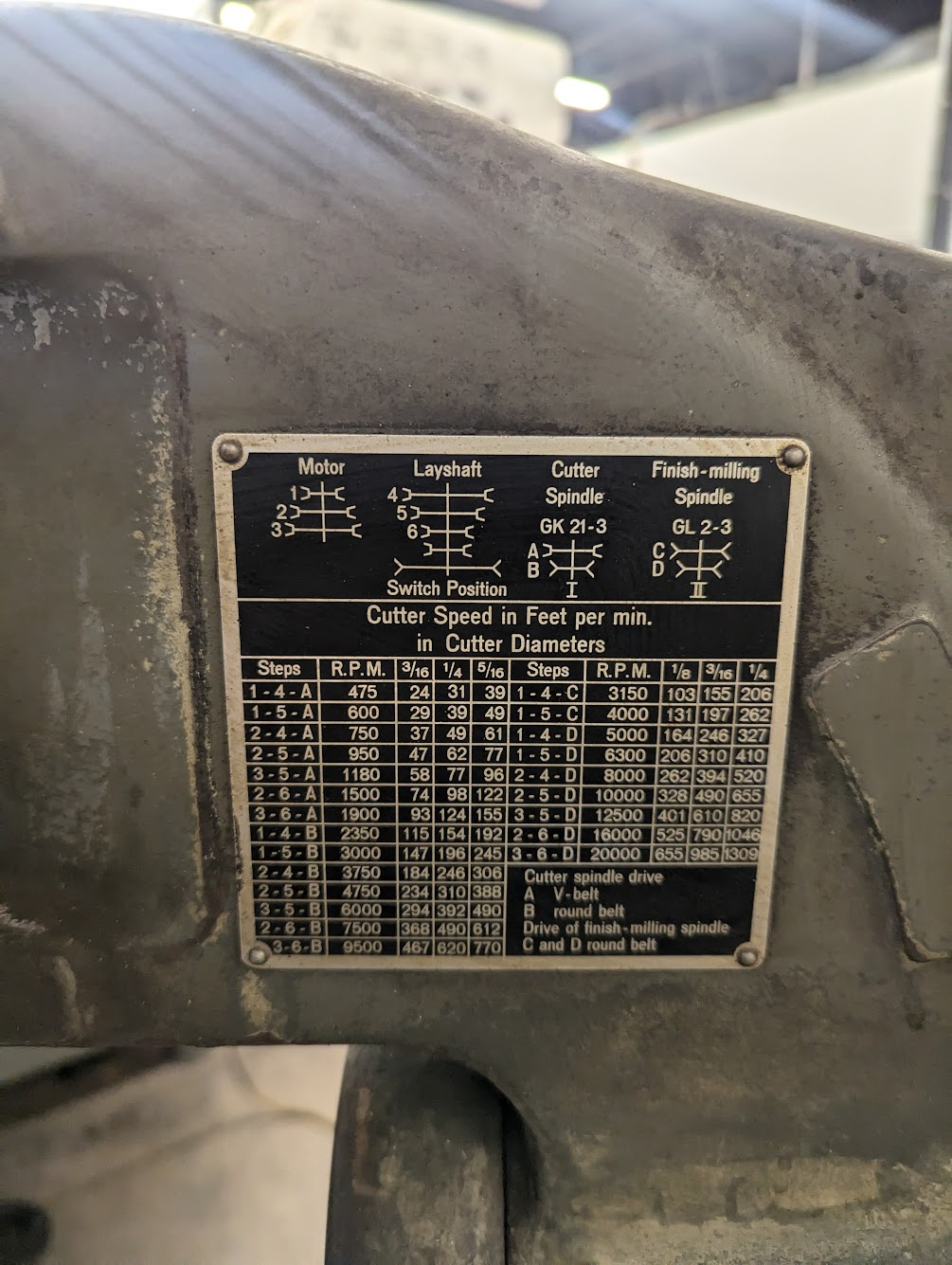

- Ensure it's at the highest speed if engraving (20k RPM); for larger bits consult the table on the plaque on the side of the machine

- Ensure all the axes are unlocked as you typically won't need to use them when engraving - X lock is underside of the machine below the knee, Knee lock is to the left of the knee wheel, Y is on the left side of the worktable.

- If needed, zero the gauges on the hand wheels by loosening the large knurled nut and hand placing the gauge at 0", before tightening it again. In basic usage, you probably won't need to do this.

- Firmly attach your engraving pattern to the pattern table. If using the pattern jig, add the end stops and ensure the knurled knobs are snugged so the pattern stays in place. Letter stencils and operator's manual are also located in the right side desk drawer.

- Insert stylus; note: the locking screw holding it in place is intentionally loose so it can be raised and lowered out of the design when doing 2D engraving.

- Load the desired engraving bit using the two collet wrenches located in the desk drawer. Use only one hand when loosening/tightening collets - snug is good, heavily cranked down is no good.

- Clamp down your stock material - you may use the stylus and the pattern jig to better align the stock to be engraved, and the toe clamp kit mounted to the side of the machine for holding it down. As with other aspects of this machine, the clamps do not need to be overly tight. Snug is good.

- Near the toe clamp set, there is a large off/on switch, move the switch to 'on'.

- Throw the red switch at the back of hte machine to turn on power, then the power switch is on the left side by the engraving table to start the spindle. NOTE: Low speed (i.e. "I") does not work, just use high speed ("II").

- Wait for the motor to come up to speed - it takes a couple seconds.

- Use cutting fluid while engaving (WD-40 for aluminum, trim-sol for mild steel)

- For fine depth adjustment, lower the loop on the front of the spindle and slide it left/right to fine adjust depth, also loosen the knurled lock ring on top of the spindle (above the brass knob) to adjust the maximum depth of cut.

- Raise the knee to the engraving depth.

- When switching to a different part/letter of the engrave, always raise the spindle before raising the stylus (otherwise it will cut through the part)

- Hold the stylus like a pencil, DON'T use the handle of the pantograph when engraving.

- Engrave the part using slow, deliberate movements of the stylus.

Recommend ~60º cutting bits; lower (such as 15º) are easily broken.

Cleanup

- Turn off power to the machine via the red large power switch that is near the toe clamp rack

- Remove stylus and put it in the drawer, along with any patterns that were used

- remove and return toe clamps to the holder attached to the machine

- Wipe down the work table with a shop rag/towel

- Remove engraving bit from the collet and ensure all wrenches are returned to the drawer

Special Setups

3D Mode

3D needs some special alignment between the main Z pivot, the milling spindle end, and the stylus, which is easy to get wrong. Also requires the stylus diameter to be the same ratio larger than the end mill (e.g. 5x larger for 5:1) and to match the topology (ball for ball nose etc.).

If trying this:

- remove the bolt and spacer/cylinder from the left side of the machine, place in the "storage" flange with hole below it.\

- Also loosen the travel limiter bolt on the right side of the main body. The arm will now travel freely in the Z axis

- Adjust the Loading/unloading dial to adjust the counter spring which supports the arm. "Loading" makes the arm lighter and want to lift, "Unloading" makes the arm heavier and want to drop.

- Use the 3D alignment bar to align the cutter and the stylus. Tighten the stylus into position with a 6mm Allen wrench.

- Proceed with 3D engraving, taking light cuts and progressively deeper cuts.

- Make sure that you've converted the machine back into 2D mode when done.

Size increases

Could swap the spindle and the stylus to do larger things, but it adds error and isn't the strong point of the machine. Requires moving the spindle and the whole tension bar etc. Never been attempted.

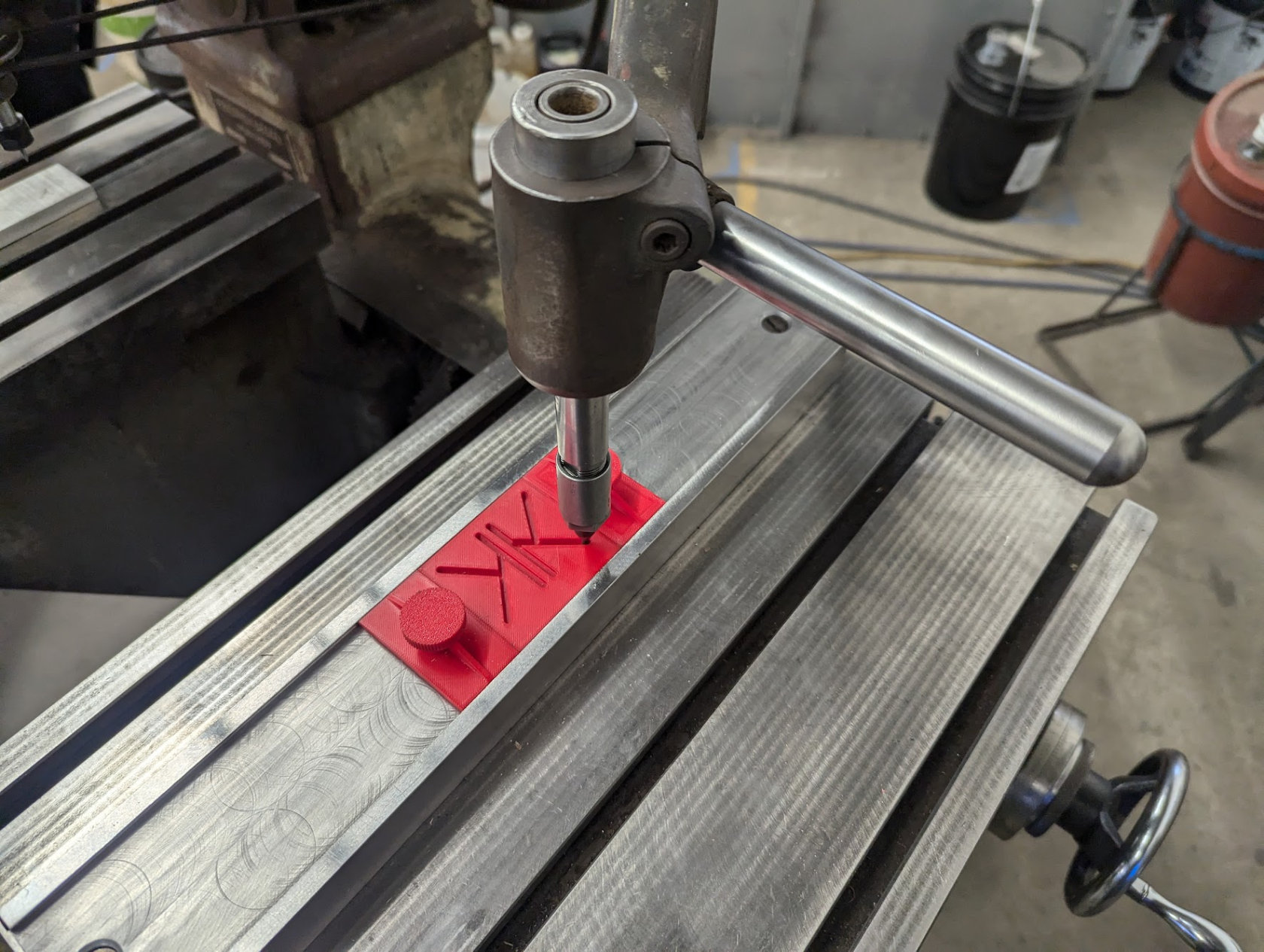

Custom 3D printed patterns for the pattern jig/bar

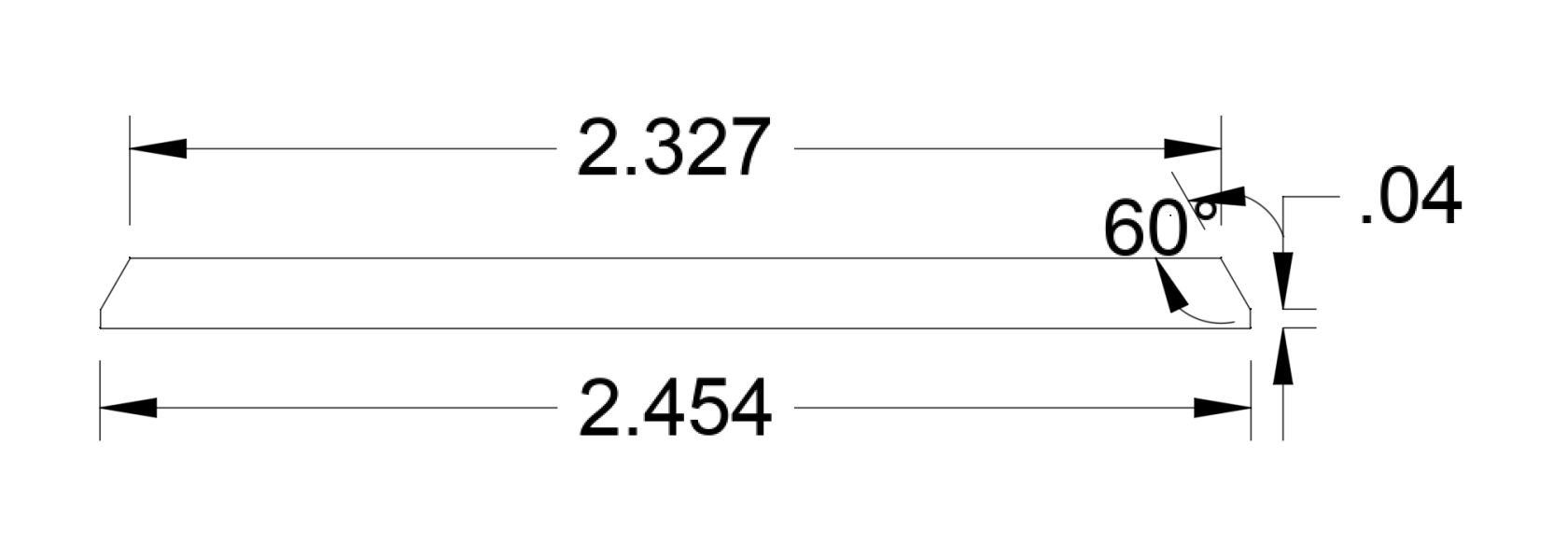

2.454" wide, 0.150" thick, with 0.040" clipped off the end, with a 60deg dovetail. You may need to file it down to size for it to fit smoothly. Blank Pantograph Template STEP File

Larger patterns can be made and held down with toe clamps. Larger patterns could be 3d printed, carved from wood, wax or any other material that can be traced from. Custom patterns that do not contain 1/8" groves to trace from will require a custom stylus to be made. Depending on the desired results, the stylus would ideally be a larger than the engraving bit/end mill by the scaling factor that is set on the bar. Ex: if a 1:5 scale is selected and a 1/8" end mill is being used, the stylus should be 5/8" in diameter.

Spare Template Files

These STEP files can be used to 3d print new letter templates.

The Letter lock is the threaded hold down at each end of the letters.

Maintenance (for techs)

Missing / potential machining projects

- There is an optional addition that mounts onto the top slide of hte machine to provide a profile to push the engraver up/down to handle circular engraving and such.

- Styluses are machined in-house out of delrin. The large end is 3/8" and the tip is a rounded 1/8" to engage with the 1/8" wide letter templates.

Every ~2 months, pump a squirt of oil into the ball oilers on each of the 5 handwheels on the machine.

No Comments