Tool Tutorial

Introduction

Notes

Safety

Hot parts, Compressed air hazard, pinch points (electric assisted lift)

Common Hazards

Hot parts

Care

Be Careful

Remove any protective film from plastic before putting it under the heater

TAKE CARE WHEN REACHING TO THE BACK OF THE MACHINE. THERE MAY BE VERY HOT SUR-

FACES IN THIS AREA.

COUNTERWEIGHTS ARE HEAVY ITEMS AND HENCE CARE MUST BE TAKEN TO PREVENT TRAP-

PING OF FINGERS.

TAKE CARE WHEN ASSEMBLING, LOADING AND UNLOADING COUNTERWEIGHT. HEAVY ITEMS

CAN CAUSE CRUSHING IF MISSHANDLED, MISSUSED OR IF DROPPED.

WHEN LOADING AND UNLOADING COUNTERWEIGHTS ENSURE THE LOCKING SPLIT PIN AND

WASHER ARE REPLACED AT THE END OF THE COUNTERWEIGHT ARM.

Do not touch the heated plastic material with your

hand or any other object during the heating cycle.

This may cause harm or damage the material itself.

Rely on the visible slight sag as the indicator for the

optimum temperature to perform the vacuum form,

or use a temperature gun to aid you.

Do not attempt to raise the table of the vacuum

forming machine when the heaters are in the

forward position. This may damage the lever

mechanism, or the heating elements. Most vacuum

forming machines have a safety mechanism that

will not allow the table to be raised unless the

heaters are in their fully back position, or for the

heaters to be pulled forwards if the table is raised.

When lowering the table, be sure to make this a

smooth and steady motion rather than dropping it.

This will prevent any damage or movement of the

mold tool within the forming area, and reduce stress

on the machine.

Always remember, this machine produces heat that

reaches very high temperatures. Do not touch or put

anything on top of the heating draw of the

machine, or put your hand under the heating

drawer itself.

Repairs to the vacuum circuit can be costly. The use of talc as a release agent is not recommended.

It may clog the vacuum pump, valves and hoses.

Note: the heater timer on the HMI display runs fast - the actual elapsed time may be less than indicated.

Do not leave auto-level on while the bed is close to the top of the machine - this will leave auto-level running, which could blow softened plastic into the heater.

Use

Consumables

None

Tooling

All tools should be mounted on a baseboard. They should not have undercuts and must be produced with

slightly angular sides (recommendations‘draft forangle’) bringingto ownaid tooling/parts:release. blades,Vent bits,holes cutters,are needed to allow the air to be evacuated

from pockets and sharp angles on the tool. Providing these holes are kept small (1mm diameter or less) they

will not leave marks on the surface of the finished moulding.

Porous mould materials such as wood and plaster should be properly sealed to prevent the vacuum pump

from sucking out any moisture or sawdust, loose plaster etc. The vacuum circuit may quickly become blocked

with dust or slurry if moulds are not properly sealed.

As the plastic cools after forming it will contract, gripping the tool tightly. If the tool has been made with

sloping sides and has a good surface finish it will release more easily. Where the draft angle must be kept to

a minimum a release agent may be used to assist release.

Sealed moulds will usually release more easily. Silicon based release agents may be used on more difficult

moulds. Silicon based release agents are rapidly absorbed by porous (unsealed) moulds, rendering them

ineffective. The use of talc as a release agent is not recommended. It may clog the vacuum circuit.

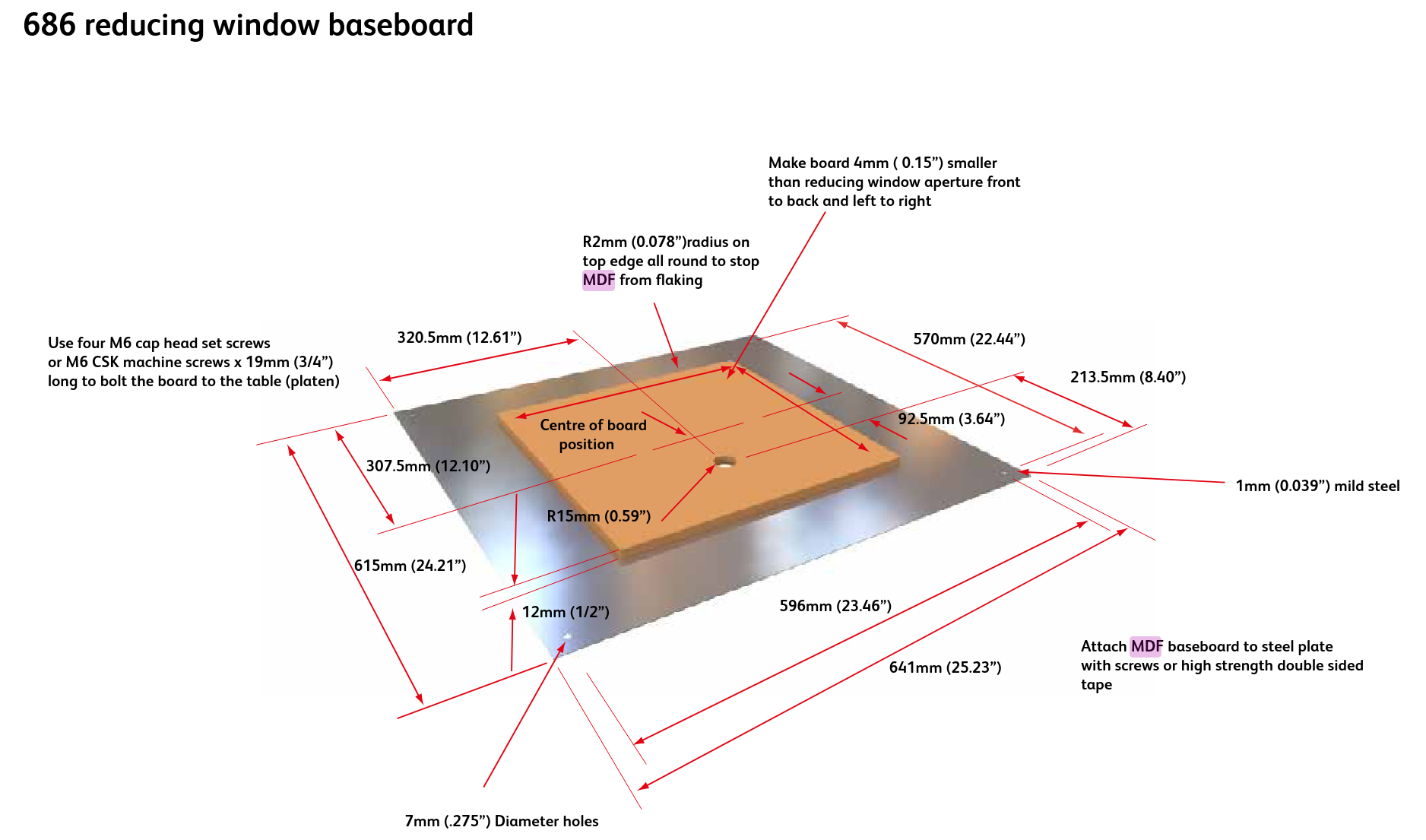

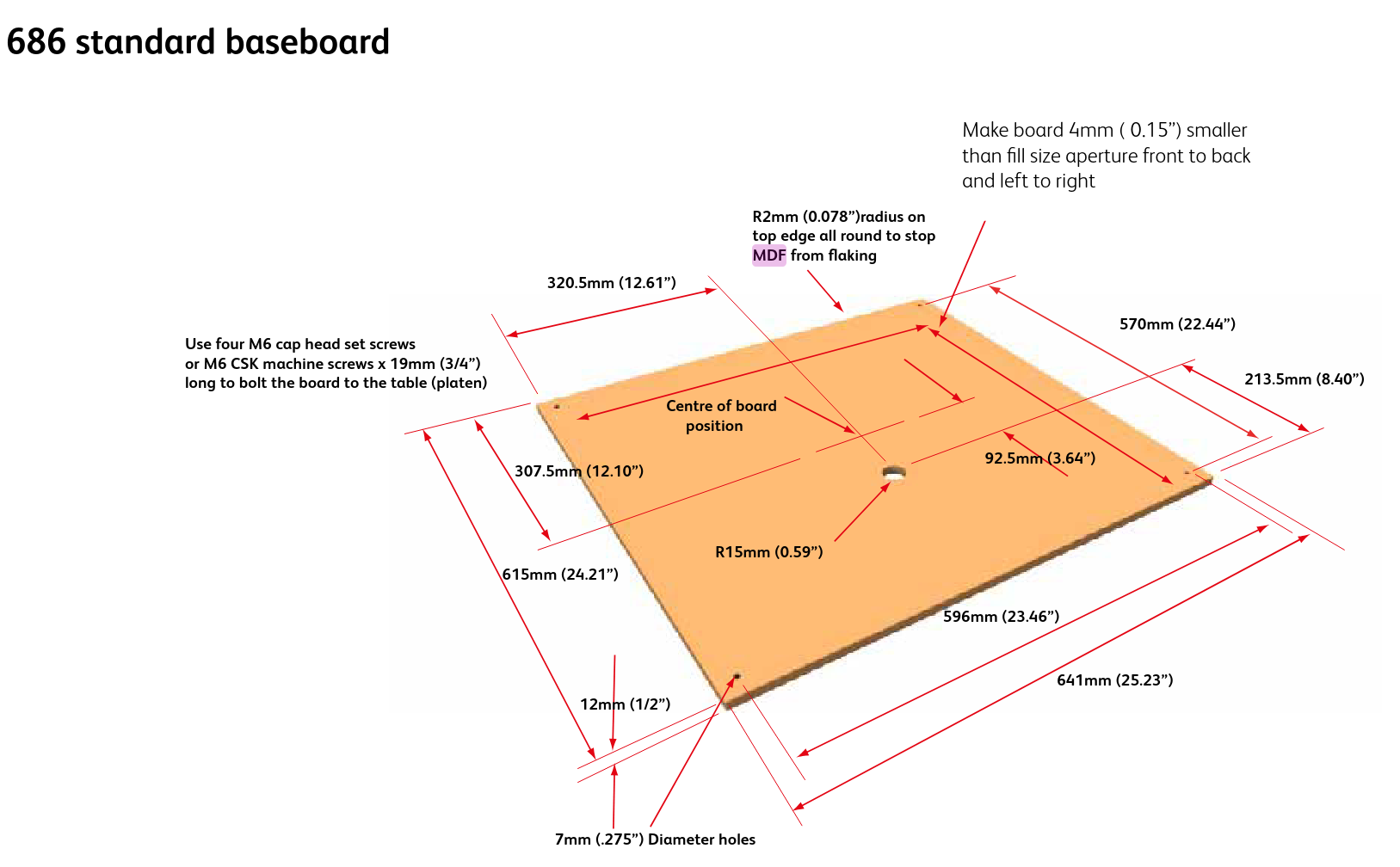

The baseboard can be made from either MDF or aluminium and needs to be 12.00mm (1/2”) thick. The

vacuum hole can be 30.00mm diameter and needs to be positioned 94mm forward of the centre of the

table.

30mm

94mm

The baseboard has to be 4mm shorter in

both directions than the forming aperture

of the machine e.g. Forming aperture

280mm x 430mm = baseboard size

276mm x 426mm.

Materials

(whatAny canthermoform plastic, thickness per manual recommendation, max size 24x24

Plastic sheet is commercially available in a wide variety of grades, thickness and cannotcolours. Materials such as

styrene and PVC are most suited to vacuum forming. Other materials such as acrylic, polypropylene and

polycarbonate will mould but difficulties may be worked with the tool)encountered.

Parts of the Tool

Annotated Image(s)

Part Description

Part Description

Part Description

The 686PT is fitted with an automatic sheet levelling system. An optical sensor directs a beam of infrared

light across the machine. The system comprises of a transmitter and receiver. When the beam is broken air

is pumped into the machine cabinet under the plastic lifting it until beam transmission is re-established. The

optical sensors are located under the top-frame at the sides.

Basic Operation

(Special topics)

Setting Up

Confirm air line is hooked up

Plug in and rotate the red switch at the back to turn on

Roll the sheet holders at the back so that the counterweights do not come in contact

Undo the clamps and lift the top plate

Insert desired frame from the cart at the back - make sure the gaskets are unobstructed and the alignment bolts at the back go through the hole on the frame

Hit "heater on" to start preheating - needs 15 mins to come to temp

START >

- LOAD DEFAULT SETTINGS -> uses system default (doesn't auto start)

- LOAD CURRENT SETTINGS

- LOAD NEW JOB

- Heater timer -> goes to heat zone select. Set all zones not in use to 0%

Workholding

Table down - use button on HMI

Table up - press both buttons on front of machine

Settings & Timing

It is important to heat the plastic material

appropriately to gain the perfect vacuum form. This

comes with the experience of just a few forming

cycles, although a good general rule is to apply 20

seconds of heat for every 0.5mm of thickness of the

plastic material.

For example, 1.5mm thick plastic requires

approximately 60 seconds of heat.

Standby settings add considerable time to the actual vacuum forming - recommend setting to the same as heating time

For 12x12 mold, recommend starting with 100% in very center heat zone, 100% in the middle ring, 0% on outside

Using the Tool

Remove any protective film from plastic before putting it under the heater. Put the plastic in smooth side down, so it seals effectively

Make sure clamps are tight

• Pull the heater forwards over the clamped plastic. The heater icon will start counting up.

• Activate the auto-level if required by touching the button so it shows green . If the plastic is sagging

and not being heated evenly then the auto-level feature is used to keep the plastic level while the heater is

forward and until ready to form a mould.

• As the plastic heats up it may begin to rise slightly. It will then soften and begin to drop back.

• When performing an initial forming it will be necessary to check the progress of heating as this will vary

with plastic type, thickness and colour. Push the heater back slightly to test the softness of the plastic ma-

nually or to observe its state. Continue with heating until it is soft enough to form. When the plastic softness

is correct push back the heater fully back.

• Press the PRE-STRETCH button to inflate the plastic before moulding if required. This feature is

particularly useful if the mould is high because it keeps the plastic at a more even thickness throughout the

moulding. If the moulding is quite high it may be necessary to pre-stretch the plastic before moulding takes

place.

• Press the two TABLE UP buttons simultaneously and hold until the table is fully raised. Then press the VA-

CUUM icon to latch on the vacuum. The moulding will form around the tooling.

• The AUTO-VACUUM feature may be enabled before bring the table up. This feature will start the

vacuum automatically when the table rises. The trigger point of the auto-vacuum sensor may be adjusted if

required.

• At the appropriate time when the plastic has formed around the mould tool the fans may be turned on to

start the plastic cooling process – press the FAN icon . When the moulding is adequately cooled, press

the fan icon again to turn it off. NOTE: WE DO NOT HAVE A FAN; THIS BUTTON DOES NOTHING

• Once the plastic has cooled sufficiently the RELEASE icon may be pressed to blow the moulding off

the mould. Too long or too soon a release may distort the moulding.

• Once released the moulding is now complete and the table may be lowered. Press the TABLE DOWN

icon and ensure the moulding has released from the mould tool. Ensure the table has reached its lower posi-

tion. Release the clamp frame to remove the moulding for inspection.

• Review the results and determine the parameters required to produce the forming. Use the settings mode

to set and record the values for later recall.