Tool Tutorial

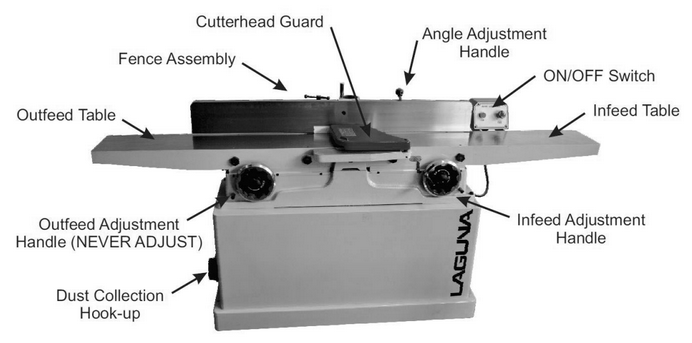

Jointer Overview

A jointer is used to flatten irregular surfaces on solid wood. The jointer uses a cutting head

with carbide cutters to create a perfectly flat and level surface on your board, removing any

warping, twisting or cupping. A jointing operation is usually the first operation performed on any

board in a fine woodworking project.

Generally, the face of a board is jointed first and then the face is held against the fence to joint

the edge. Multiple passes may be needed to ensure a flat surface is machined. By creating two

perfectly flat sides that are perpendicular to each other, future cuts, machining operations, and

assembly will benefit.

Jointer-Specific Safety

• Even though the jointer blade has a guard to cover the

exposed cutting head, care should be taken to keep

hands, hair and clothing away from the cutting head.

Maintain 3” safety margin around the cutting head at

all times

• Never apply downward pressure to the board directly

over the cutting head

• Position your hands away from the very end of the board and practice pushing material

through in a smooth motion

• Maintain a balanced stance at all times to avoid falling into the machine should the

board slip

• Do not overreach or use excessive force to perform any operations

• Use pushing devices, such as push sticks or blocks, to keep hands clear of the cutting

head

Solid wood is the only material allowed on the jointer. Plywood, MDF, plastics and

metals are not allowed. Consult a TechShop DC for advice when jointing exceptionally

dense hardwoods

• Use good quality wood on the jointer. Avoid wood with loose knots, splits, nails, screws,

paint or other foreign objects in or on it

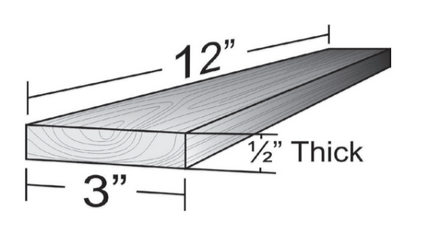

• Wood should be more than 3” wide, 1/2” thick, and 12”

long for use on the jointer

• Never back a board out of the jointer. If the board becomes

stuck, stop the machine before trying to remove it

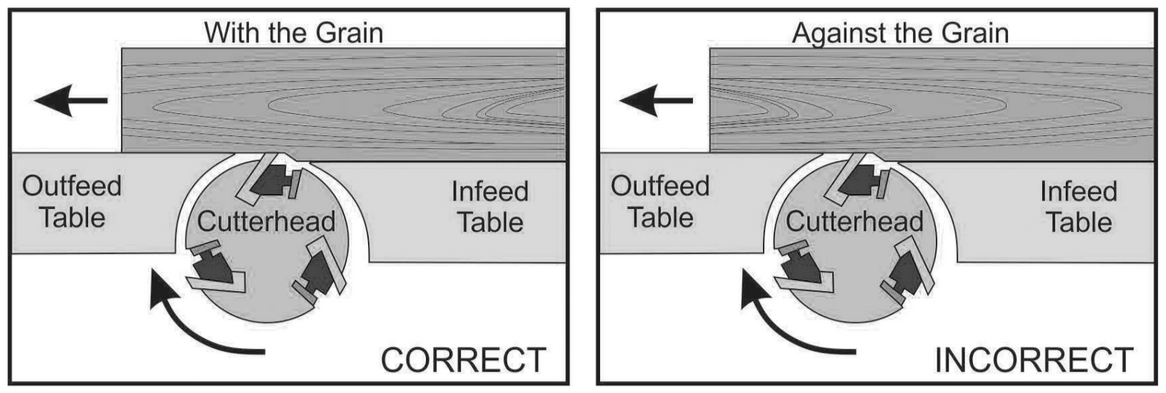

• Joint in the same direction that the grain runs along the

board to avoid kickbacks and poor surface finish. Consult a TechShop DC if cutting

across the grain is necessary

• It’s easier on both machine and operator to make several small passes instead of one

very large pass

• Check the cutting depth before beginning any work and set the cutting depth back to

1/16” when finished

• The cutting head takes a long time to spin down. Do not leave the machine or change

any settings until it has come to a complete stop

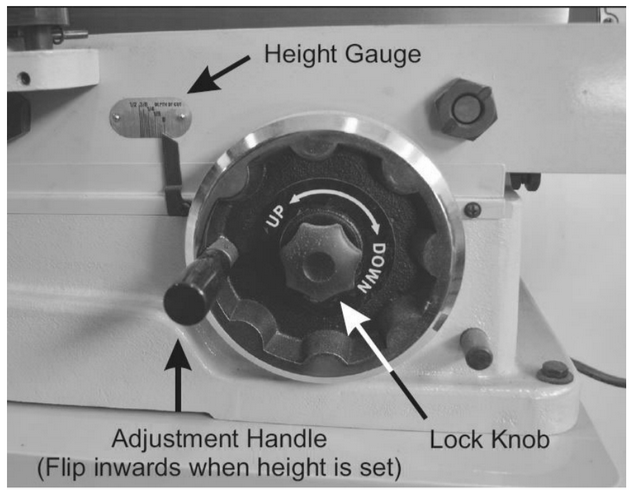

Adjusting the Infeed Table Height

The height of the infeed table determines the thickness of the cut and the amount of material

removed from your board. Depending on the width, density, and desired finish of your board,

you may set the infeed table height higher or lower. A good starting point is 1/16” passes.

Consult a TechShop DC for advice if things

aren’t working out as you expect.

1. Turn the lock knob counter clockwise to

unlock the height adjustment.

2. Flip the height adjustment handle out

and rotate the height adjustment to your

desired cut thickness.

3. Flip the height adjustment handle back in

and lock the height adjustment by turning

the lock knob clockwise until it is snug.

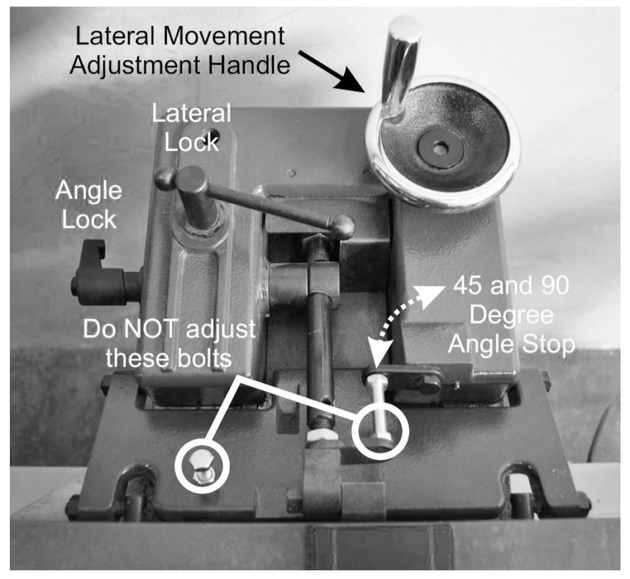

Adjusting the Jointer Fence

The jointer fence serves many purposes. Its main purpose is to hold your board perpendicular

to the cutting head and tables. The angle can be changed to put a specific angle along the

edge of a board and it can be moved across the machine to move the location of your board

relative to the cutting head to help even the wear out along the teeth.

Users can adjust the fence angle between 45 and 90 degrees. Consult a TechShop DC to

adjust the fence to angles less than 45 degrees. It’s good practice to check the fence angle

before machining any boards.

Adjust the Fence Angle

1. Loosen the angle lock and flip the angle

stop out of the way.

2. Use an angle gauge to set the fence to

the desired angle.

3. Tighten the angle lock and double check

the fence angle with the angle gauge.

Adjust the Fence Position

1. Loosen the lateral lock.

2. Turn the lateral crank handle until the

fence is at the desired position.

3. Tighten the lateral lock.

Basic Operation

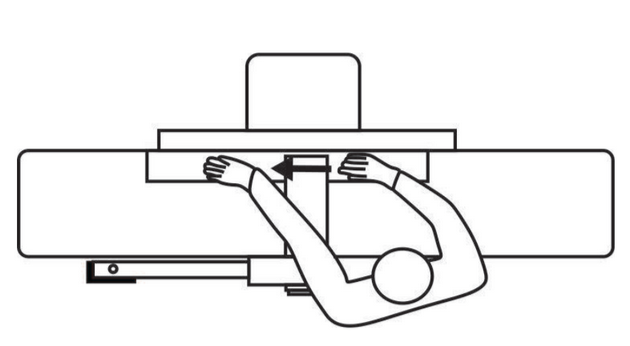

1. Stand along side the machine, opposite the

fence. This position allows you to reach

both the infeed and outfeed tables and

keeps you safe from any kickbacks.

2. Turn the jointer on and let the cutting head

get up to full speed.

3. Hold the board firmly against the infeed

table and fence, a few inches away from

the blade guard.

4. Hold the board to the infeed table with your left hand

and feed it slowly and smoothly into the cutting head

with your right hand.

5. Once there is about 6” of board on the outfeed table,

move your left hand to hold the board firmly to the

outfeed table and against the fence.

6. Continue feeding the board through the cutting head with your right hand, and keeping

pressure on the outfeed side with your left. Try to keep the downward pressure on your

board near the cutting head on the outfeed table.

7. When your right hand is near the cutting head, move to the outfeed table and pull the

board the rest of the way through the jointer.

8. Continue making passes until the face is flat. Make a light pencil mark across the

surface of your board as a visual reference. When the mark disappears fully, you’ll

know the face is flat.

Tips and Tricks

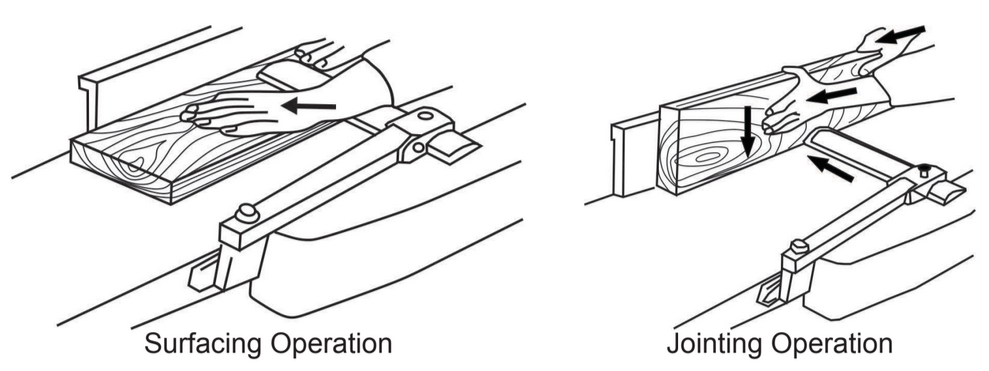

Perform a surfacing operation first, then hold the freshly machined surface to the fence and

perform a jointing operation.

Grain direction may cause issues with feeding the board and surface finish. Machine with the

grain of the board for a smooth surface and minimal chance of kickbacks.

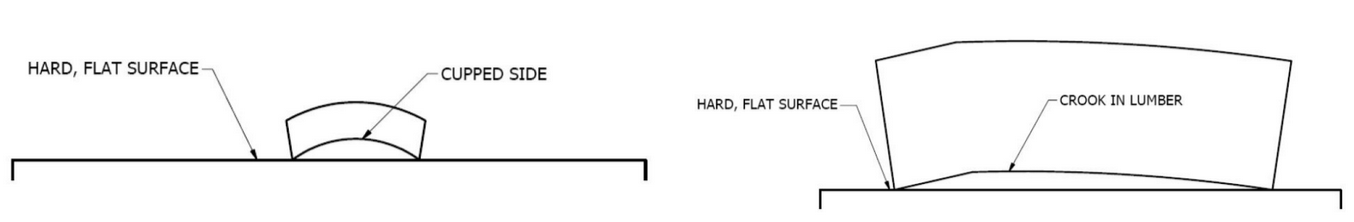

Place the cupped or crooked side down on the jointer for the easiest side to machine flat.