Tool Tutorial

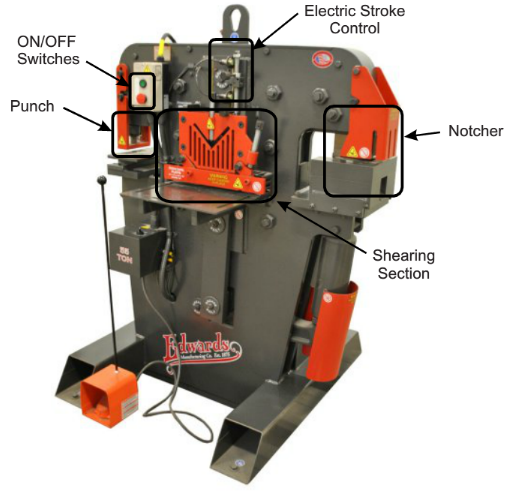

Edwards 55 Ton Ironworker

The ironworker’s main strength is its versatility. It can shear, punch, and notch a variety of

different materials. It can work with plate metals that greatly exceed the capacities of many ofthe other machines at TechShop. The ironworker consists of three primary sections: The shear,

the notcher and the punch.

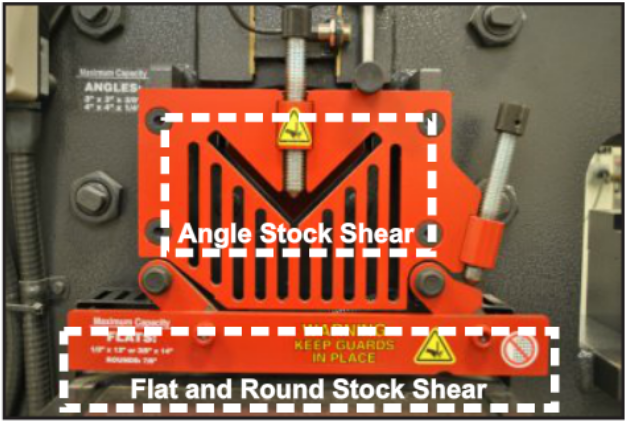

Shear

This section of the machine can shear angle, round stock, and flat stock of varying thicknesses. The

shear section of the ironworker consists of a dedicated angle shear and a dedicated flat and

round stock shear.

Angle Iron Shear

The angle iron section of the machine consists of

an angled slot through which material is fed to be

sheared. A “V” shaped blade shears the material

when the pedal is depressed. The shear can cut thick : i /

angle iron which is very inefficient and harder to hold /

safely on the cold saw and horizontal bandsaw. When

cutting very large pieces be sure to have someone

behind the machine catching the cut pieces. This will

help prevent damage to the machine and others.

Flat and Round Stock Shear

The flat stock section of the shear allows the user to shear thick plate and round stock metals

very quickly. Pieces that cannot be appropriately held on the bandsaw and can fit within the

size requirements should be sheared on the ironworker.

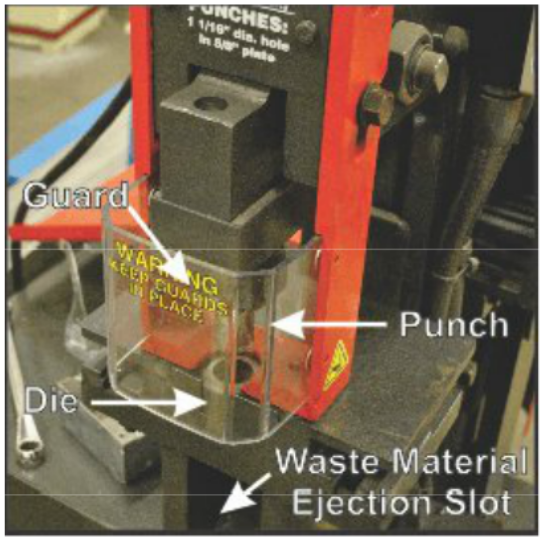

Punch

The punch will punch holes in very heavy gauge material.

This tool works very well with all types of plate materials. It

will punch through thick plate steel in a couple of seconds

where the drill press would take minutes. The hole sizes

are limited to the punch and die sets that are available.

Punch and die sets are available in different shapes such

as round, square, rectangle, hex, oblong. TechShopProtohaven has

common sizes in square and round. If a specific die isneeded needed, it can be purchased from the manufacturer. If a

hole is needed that is in between available hole sizessizes, a

hole can be punched slightly smaller than the desired

hole size. This hole can then quickly be enlarged on the

drill press. Ask a TechShopshop facilities staff membertech for

assistance if you need help changing dies. Do not change punch and die sets yourself.

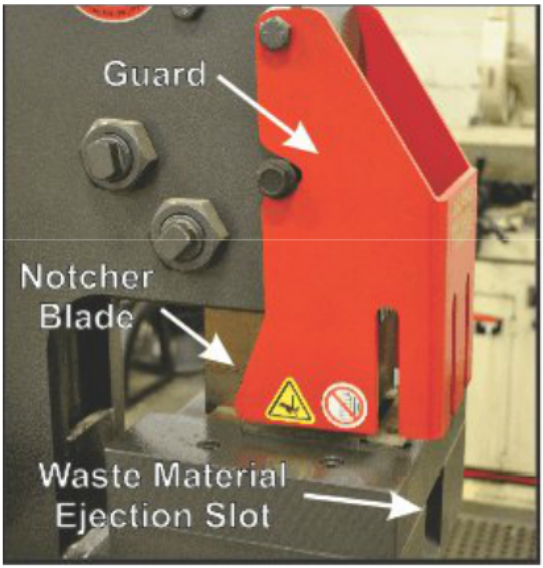

Notcher

The notcher is used to cut notches out of material for a

variety of purposes. When a piece needs to fit within a

slot, a tongue can be created by removing a square chunk

of material from both sides. Any angle can be cut on the

notcher by moving the material to the desired angle.

One of the most useful applications for the notcher is for N,‘;,‘:('}fir

removing sections of one leg of angle stock frofor assembly \

purposes. This operation would require multiple steps on ] ()

other machines but can be done in one quick step on the

ironworker.

Safety Features & Precautions

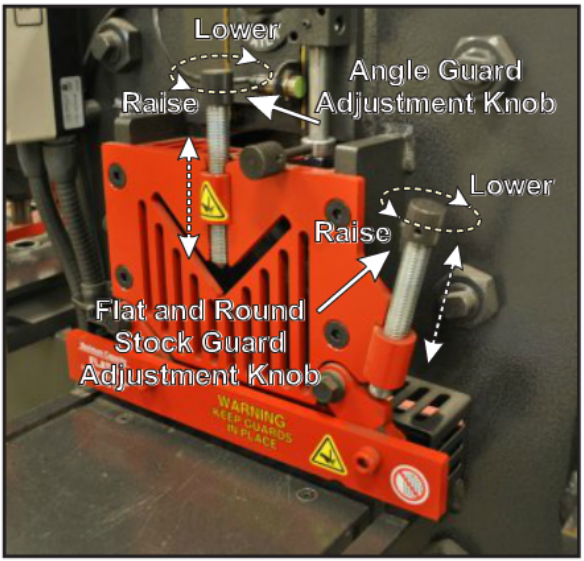

Machine Guards

Each section of the ironworker has a guard to prevent injury to the user during operation. It is

imperative that guards remain seated slightly above the material you are working with. This

prevents injury and damage to the machine and your work.

Shear

There are two shear guards. There is one guard for : 3

securing angle stock and another for securing flat and wl Angle Guardi H H2k'\’AfjustimentKnob

round stock. When working on this machine make sure i X

the guard is lowered to the height of your material. It :

needs to be almost touching your material. The guard i

should be no further away from your material than 1/32”

- 1/16” for flat and round stock and should make contact

with angle stock.

The guards on the shear are raised and lowered by turn-ingturning a screw. The angle stock guard consists of a screw

with a tapered end to secure the material. Secure angle

stock tightly with this screw. The flat and round stock

guard consists of a bar that is lowered by a screw. It is not spring loaded so it will need to be

moved up by hand when it needs to be raised. Simply turning the screw counter clockwise will

not raise the flat and round stock guard.

The material ejection ports on the back of the shear are covered to prevent access to the

blades while the machine is in operation. When cutting large or heavy material make sure you

have someone catching the material as it is cut. This will

prevent damage to the machine and others.

Punch

The guard on the punch should always be seated very

close to the material while the machine is in operation.

The guard should be located 1/32"-1/16” above the ma-terialmaterial being punched. Extra space should be made for

the material as it will slightly deform after being punched

and will then be impossible to remove from the machine

without moving the guard. The guard is moved by loosen-

ing the bolts on either side, then lifting it up or down as

needed and then re-tightening the bolts.

Notcher

The notcher guard helps prevent injury from the tool. The Bolte

notcher should always be operated with the guard down shouldand beand

lowered

to

1/32”

-

1/16”

above

the

material.

The

guard HoH

swings out towards the operator and is tightened in place

with two bolts. Make sure the bolts are tightened before

operating the machine. The notcher guard is set to a fixed

height for the maximum material thickness. The guard

placement should not need to be adjusted. The slots in the ;) Guard,_height

guard are designed for usage with angle stock and allow cannot

clearance for the vertical leg of the material. Bebdiusred

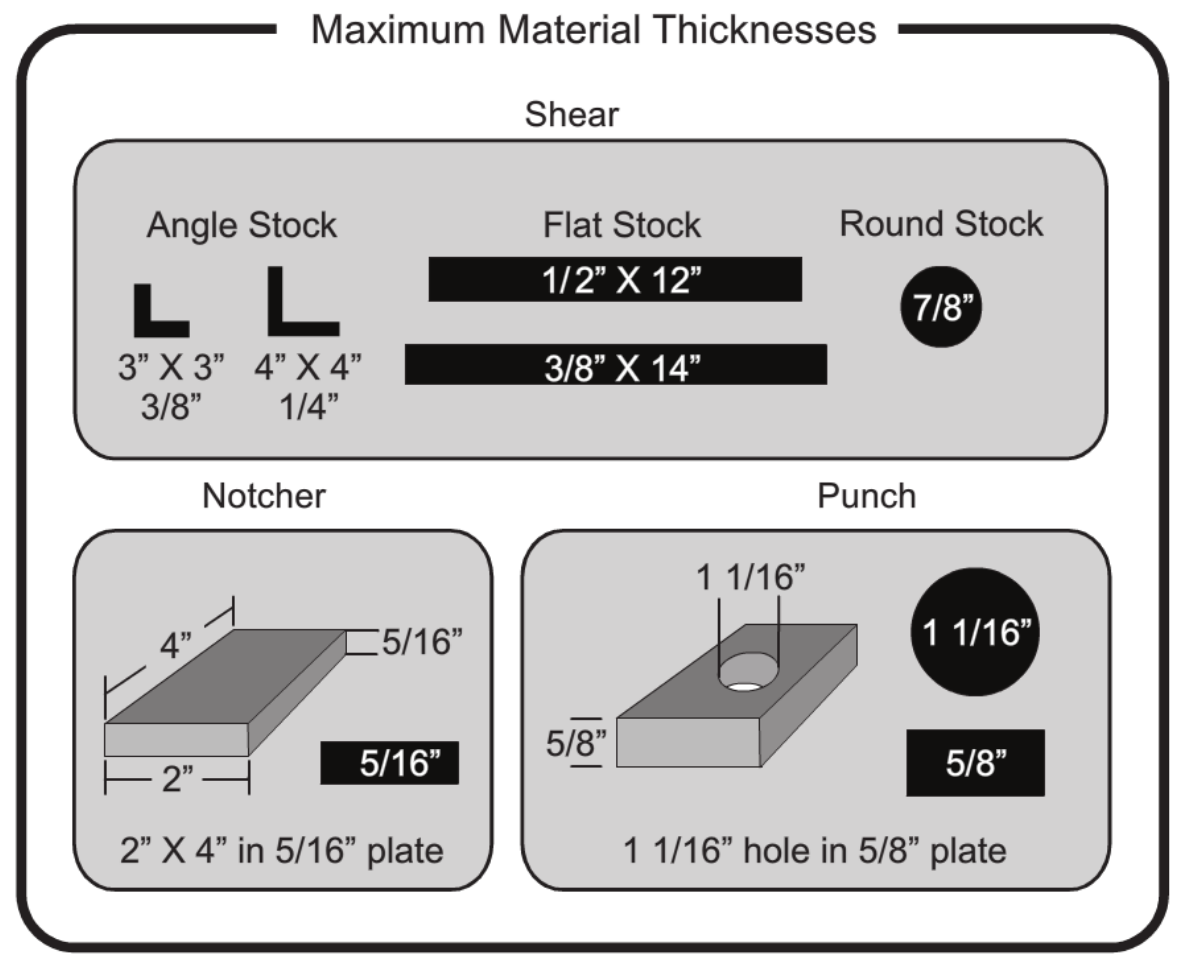

Maximum Material Capacity

The ironworker is capable of shearing, punching and notching very thick plate metals but it

is very important that the maximum capacities of the machine are followed. Damage to the

machine will be minimizedyminimized by following these capacities. The capacity of each section of the

machine are clearly labeled. Please refer to the labels on the machine or in the following chart

for the maximum material capacities of the ironworker. Tool steels are not to be used on this

machine. Stainless steel can be used but not at the maximum thickness capacities of the

machine. Always check with a TechShopshop facilities staff membertech anytime you want to use the

machine for materials harder than mild steel.

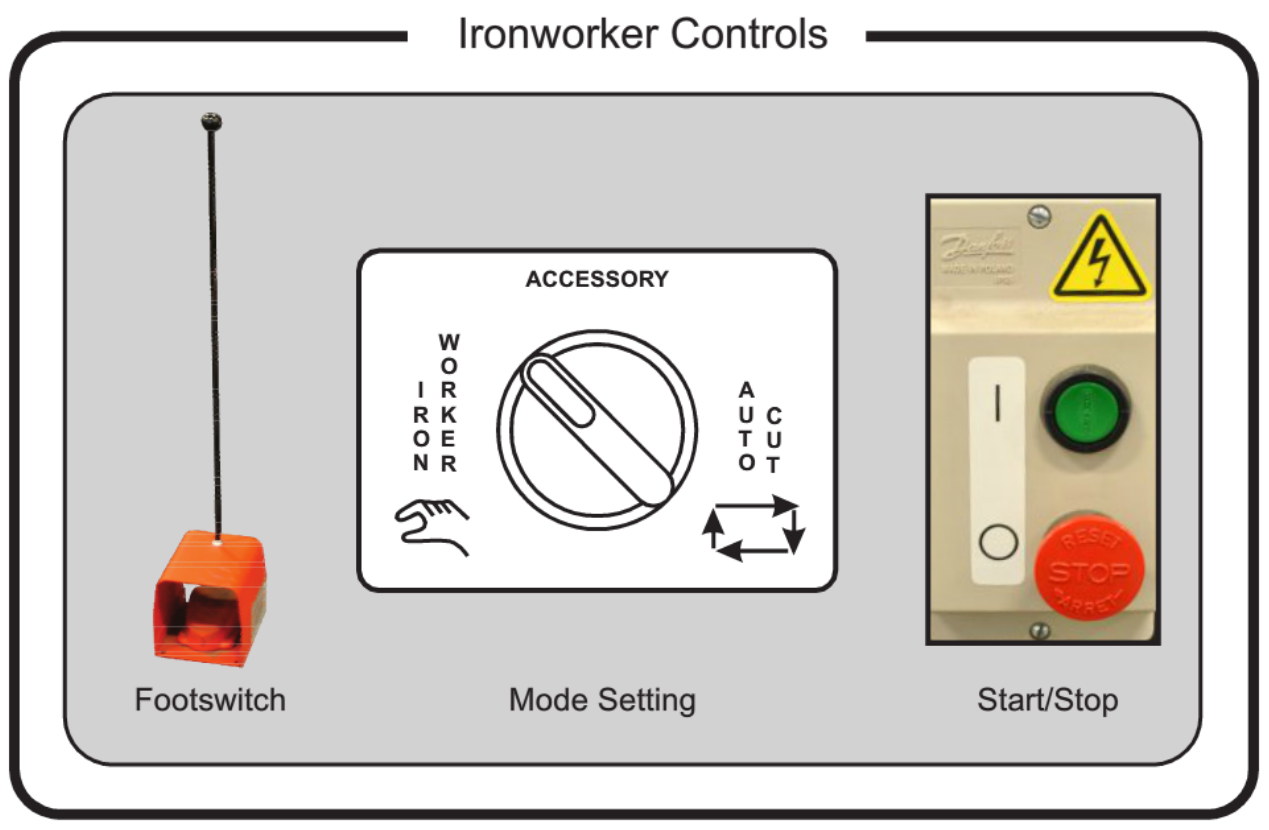

Controls

The ironworker controls are very basic. There is a start and stop button that turns the ma-chinemachine on and off. A footswitch actuates the movement of the machine. When the footswitch is

depressed and held, the shear, punch and notcher run through one full cycle of movement.Al All three tools move simultaneously. Three different modes are available that can be selected

when the machine is not running. The available modes are ironworker, accessory, and autocut.autocut.

Ironworker Mode

When the ironworker mode is selected the shear, punch, and notcher are available for use.

This is the primary mode for the ironworker.

Accessory Mode

This mode is selected when the ironworker’s hydraulic tube and pipe bender attachment is

used. The ironworker’s power is fed to the hydraulic bender and none of the ironworker’s tools

(shear, punch, notcher) will move when the bender is in use.Usage of the hydraulic bender requires a seperate SBU class.

Auto Cut Mode

The auto cut mode is used when an attachable auto cut device is used. The auto cut device

plugs into the back of the machine and is used for shearing operations. It consists of a

movable stop with a trigger. When the trigger is hit the ironworker will engage and cut the

material at the desired length. This device is not currently available at TechShop.available.

Basic Operation

Shear

The distance from the angle stock guard front face to the blade is 4 13/16” and the distance

from the flat and round stock guard front face to the blade is 5 7/16”. Make sure to account for

this distance when cutting your material by adding it to the length you desire to cut and then

align your mark to the front face of the guard.

Cutting Flat or Round Stock

- Mark material with sharpie or scribe at desired cut length.

- Place material on bed.

- Move material to desired location for cut.

- Set guard to 1/32"-1/16” above material by turning the adjustment knob.

- Turn machine ON by pressing the green button.

oo~WNo. - When hands are free of any pinch points and NOT located under your material depress

the footswitch.7. - Release the foot pedal when the machine has completed one full cycle and the blades

have returned to their starting position.8. - Turn the machine OFF by pressing the red button when all cutting is complete.

9. - Dispose of any scrap material in the metal scrap bin.

Cutting Angle Stock

- Mark material with sharpie or scribe at desired cut length.

- Place material into angle stock slot.

- Move material to desired location for cut.

- Turning the adjustment knob until the tapered screw has made contact with the material.

- Turn machine ON by pressing the green button.

oo~WNo. - When hands are free of any pinch points and NOT located under your material depress

the footswitch.7. - Release the foot pedal when the machine has completed one full cycle and the blades

have returned to their starting position.8. - Turn the machine OFF by pressing the red button when all cutting is complete.

9. - Dispose of any scrap material in the metal scrap bin

Punch

1.

- Use center punch to mark desired location of hole.

2. - Place material on bed.

3. - Move material to desired location for cut.

4. - Set guard to 1/32°-1/16” above material by loosening the guard bolts, moving the guard

and then re-tightening the guard bolts.5. - Turn machine ON by pressing the green button.

6. - When hands are free of any pinch points and NOT located under your material depress

the footswitch.7. - Release the foot pedal when the machine has completed one full cycle and the blades

have returned to their starting position.8. - Turn the machine OFF by pressing the red button when all cutting is complete.

9. - Dispose of any scrap material in the metal scrap bin.

The punch can be very loud and starttlingstartling to other members when in operation. Verbally notify

other members when performing punching operations.operations with large diameters.

Notcher

1.

- Draw desired cut on material with sharpie or scribe.

2. - Place material onto the bed.

3. - Set guard to 1/32”-1/16” above material by loosening the guard bolts, pivoting the guard

to correct location and then re-tightening the guard bolts.4. - Turn machine ON by pressing the green button.

5. - When hands are free of any pinch points and NOT located under your material depress

the footswitch.6. - Release the foot pedal when the machine has completed one full cycle and the blades

have returned to their starting position.7. - Turn the machine OFF by pressing the red button when all cutting is complete.

8. - Dispose of any scrap material in the metal scrap bin.

Useful Links

http://www.edwardsironworkers.com/

- Machine manufacturers website

http://www.americanpunchco.com/punch_die_setup_tips.htm

Hole punching tips and trickshttp://coloradok5.com/forums/archive/index.php/t-266090.html

Ironworker tips and tricks

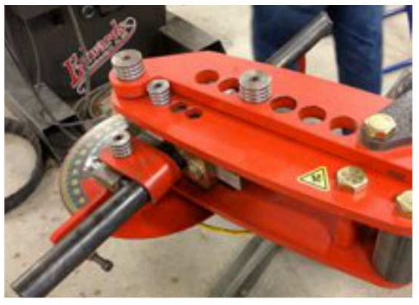

Edwards 10-Ton Tube and Pipe Bender

The tube and pipe bender is a quick-connect hydraulic tool that expands the

capabilities of the Ironworker. It is designed for medium to heavy duty material,

bends up to 2” (1.D.) Schedule 40 pipe, 2.5” (O.D.) tube and 2” square tube

quickly and accurately.

Pipe Bending

To bend pipe on the pipe bender you need to have the proper dies for the size

pipe you want to bend. At TechShop we currently have pipe dies for you to

choose

from.

Connecting the Pipe Bender

Once you have rolled the pipe bender near the Ironworker you have to connect it

to the Ironworker. There are three cables bundled together and then the remote.

The male and female hydraulic connections go to their opposites and the remote

cable goes in the top plug labeled accessory control. The yellow cable operates

the limit switch you can set where you want your bend to stop, it plugs into the

plug labeled limit switch.

Setting up the Pipe Bender

After connecting the pipe bender to the Ironworker, it’s time to set up your bend.

First, you need to find the right size

die

for

your

pipe.

Second, you need to decide if you are bending horizontally or vertically. There

needs to be enough clearance around the bender for your material to move

during the bend without hitting anything.

*NOTE: If you have a long pipe you are bending there is more room for the end

of the pipe if you bend it vertically towards the sky. Smaller length pipe that will

not contact with the things sitting around the bender can be done horizontally.

Once you have chosen the correct

size die for your pipe, start by putting

the die on the bender with the large

pin going through the arms of the

bender and the center of your die.

Next, take your backstop that matches

the die and install it on the non-

moving arm of the bender with

another pin. Make sure that the screw

is towards the bottom of the bender.

Now you can slide your pipe into the

bender between the die and backstop.

The collar that holds the pipe goes on

next using the short pin.

*NOTE: If you are making a bend at

the end of a piece of pipe you want to

make sure that it is even with the end

of the die.

' Once the pipe is where you want it in

the die, tighten down the set bolt with

a 3/4” wrench. Do not over tighten the

bolt.

Making

a

Bend

The pipe bender has an angle finder

to locate the degree bend you want to

make.

To make a 90-degree bend you are

going to have to make two 45-degree

bends using the step pin on the pipe

die.

For your first bend line up the die on

the angle finder to 0-degree.

Now press the remote OUT button to

start the bend.

When you reach the end of the first

step, jog the bender back with the IN

button to make it easier to remove the

step

pin.

Now adjust the step pin to the next

hole in the die to finish the 90-degree

bend.

To safely remove your pipe, jog the bender back using the IN button to relieve

the pressure on the pipe. Remove the collar, step pin and backstop to remove

your pipe.

The dies at TechShop are for 90-degree bends. To make a 180-degree bend

with these dies you must move the pipe forward after the first 90-degrees to

ensure that you will not pinch the pipe on the die, which will make it almost

impossible to remove the pipe from the bender.

*NOTE: The minimum length of pipe to use on the bender is 15”.