Tool Tutorial

(Link to PDF Tool Tutorial)

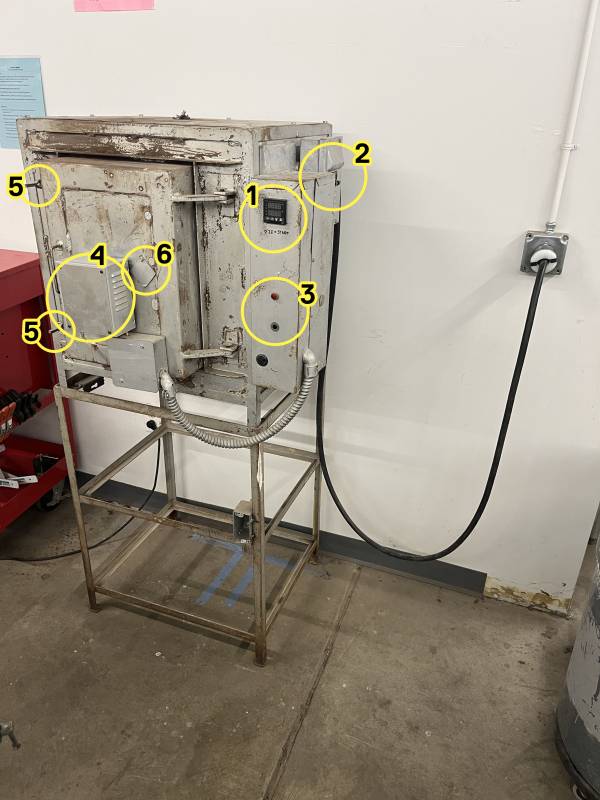

Tool anatomy

1. Controller 2. Breaker switches 3. Alarm lights 4. Temperature probe 5. Latches 6. Viewing port

To do

-

open & inspect electronics panel for safety

-

order & install alarm buzzer-lights

-

apply a better door seal

4/18 "does it work" test

T value = time until next step

| Step | Set Temp (˚F) | T value | Check time | Check temp | Notes |

|---|---|---|---|---|---|

| 1 | 80 | 15 | 10:33 | 75 | |

| 2 | 300 | 15 | 10:48 | 295 | 213˚/15min = ~14˚/min |

| 3 | 0 | -121 | 11:03 | 265 | it definitely works |

4/18 "is there an alarm buzzer" test

-

AL1: Set ALM1 to 1000˚

-

AL2: Set Hy-2 to 10˚

Asked the kiln to try to ramp to 2k˚ in 15 minutes. The alarm relays are firing, but no alarm light or buzzer sounds, so we need to get one (or two).

| Step | Temp (˚F) | T value | Check time | Check temp | Notes |

|---|---|---|---|---|---|

| 1 | 80 | 15 | step skipped | ||

| 2 | 300 | 15 | 11:40 | 300 | AL2 light on, no buzzer |

| 3 | 2000 | 180 | 12:00 | 550 | proceeding to “can we get to 2k” test |

| 12:03 | 600 | ||||

| 12:07 | 661 | ||||

| 12:15 | 766 | ||||

| 12:21 | 839 | ||||

| 12:27 | 896 | ||||

| 12:34 | 958 | ||||

| 12:54 | 1099 | AL1 light on, no buzzer | |||

| 1:25 | 1250 | ||||

| 1:35 | 1284 | ||||

| 1:47 | 1331 | ||||

| 2:09 | 1386 | ||||

| 2:11 | 1400 | ||||

| 2:32 | 1454 | ||||

| 2:51 | 1492 | ||||

| 3:45 | ~1570 | hovering around here, jumping rapidly up and down. the area around the kiln is warm. this is about the functional limit of this configuration. | |||

| 4 | 80 | -121 | |||

Forge curing schedule

There's a forge which has been lined but needs to be heat-cured.

| Step | Temp (˚F) | T value | Notes |

|---|---|---|---|

| 1 | 100 | 60 | ramping up 100˚/hr |

| 2 | 200 | 60 | |

| 3 | 300 | 60 | |

| 4 | 400 | 60 | |

| 5 | 500 | 60 | |

| 6 | 600 | 60 | |

| 7 | 700 | 60 | |

| 8 | 800 | 60 | |

| 9 | 900 | 60 | |

| 10 | 1000 | 60 | |

| 11 | 1100 | 60 | |

| 12 | 1200 | 30 | holding for 1/2 hour for 1/2“ of material |

| 13 | 80 | -121 | stop |

The official kast-o-lite packet says to ramp down 100˚ per hour, but people online seem to skip this step.

Temperature test notes

| Temperature | Time |

| 250F | T=0 |

| 1500F | T+45min |

| 1750F | T+70min |

| 2000F | T+140min |

Ramp down to 1500F |

+15 mins |

misc notes

-

it's possible to store several simple programs; there are 30 steps total

-

it's possible to set a schedule which is impossible for the machine to achieve

-

telling people in plain english how to set alarms for each type of project is important

-

the alarms don't stop anything and are not a safety feature so much as an alert

-

it's possible to observe and change the schedule while it's in progress

To set a single temperature:

- press A/M. Display should show C-1

- use up/down arrows to set first digit, then press A/M to move on to next digit. Repeat until last digit is set

- Don't touch anything; wait a few seconds and it should start heating.