Tool Tutorial

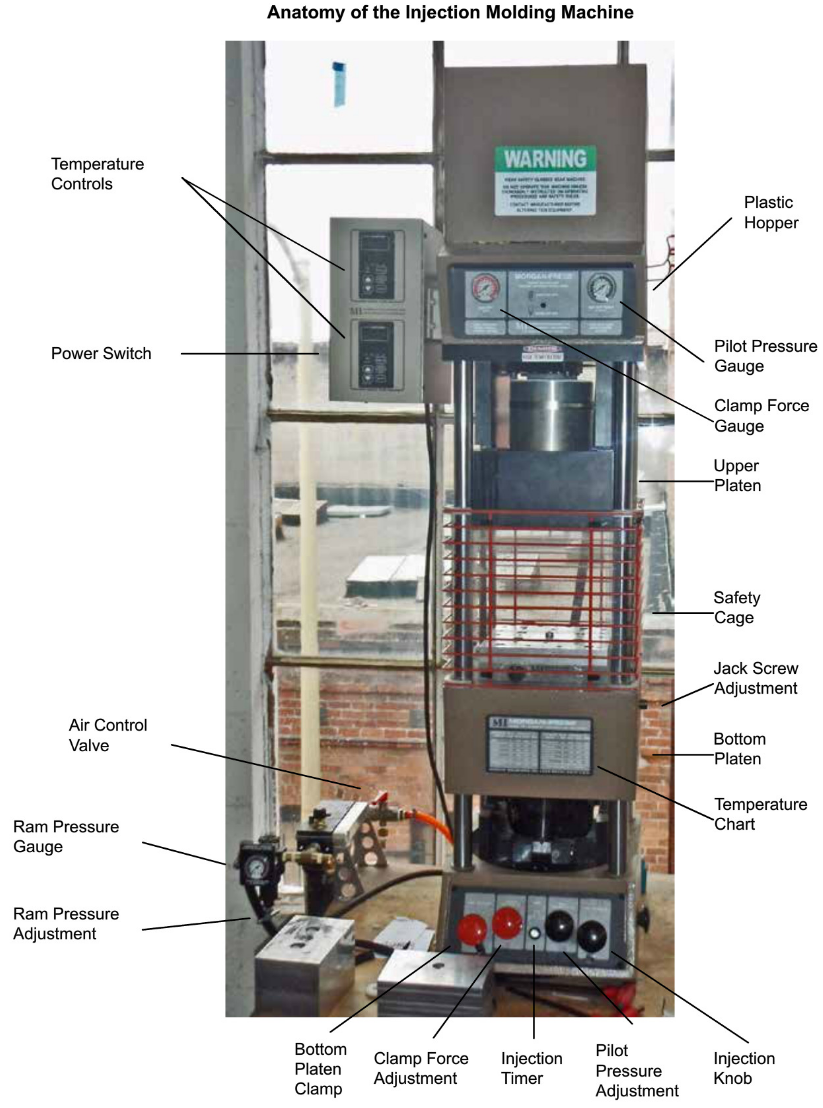

Morgan Industries G-100T Injection Molding Machine Overview

The injection-molding machine forms plastic parts by melting plastic and forcing the plastic into a

multi-plate mold that is held in a powerful clamp. After the plastic solidifies, the clamp is released,

allowing the finished part to be removed from the mold.

The basic cycle is clamp, melt, inject, pack, solidify, unclamp, eject.

Clamp: The two (or more) parts of the mold are brought together and held under pressure by a

strong clamp.

Melt: Feed stock material is brought up to melting temperature and becomes a viscous liquid.

This is often called “the melt.”

Inject: The melt is forced into the mold cavity, filling it completely.

Pack: The melt is held at pressure inside the mold until the gate solidifies. (The “gate” is the final

orifice that material flows through into the cavity.)

Solidify: The material is allowed to harden in the mold. As it solidifies, it will shrink. The amount of

shrink depends on the material and your process.

Unclamp: The parts of the mold are pulled apart to allow the work piece to be removed.

Eject: The work piece is removed from the mold and allowed to continue to cool. It may shrink

further as it cools.

On the G-100T, all of these processes are manually controlled. This provides great flexibility and

allows you to use complex molds without having to do any complicated controller programming.

In injection molding, the key to quality is a consistent process. Since with our machine you are the

controller, you will get the best results by developing a rhythm and keeping up a comfortable and

consistent pace as you make parts.

Injection Molder Safety and Procedures

« Some parts of the machine are hot and can cause severe burns

* Hot plastic is sticky and can cause severe burns

» Wear leather or heat-resistant gloves to protect your hands from hot molds and plastic

« The machine has a powerful clamp that can cause crushing injuries. Do not defeat the safety

interlock, and watch for fingers around the lower platen when clamping and unclamping

« The machine has a powerful ram that can cause crushing injuries. Do not defeat the safety

interlock. Do not open the feed chute door before the ram has completed its return stroke

+ Know what, if anything, your chosen material out-gasses during the melt phase and ensure

adequate ventilation

* Know the correct process temperatures for your material. Avoid excessive process

temperatures. Some resins give off noxious fumes when overheated, and all will quickly

degrade. Excessive temperatures don’t help — imagine melting ice cubes — water at 80°F isn’t

any more liquid than water at 40°F — so, too, with plastic

* Do not process “mystery material.” It may out-gas unacceptable fumes, or may be corrosive.

Know the properties of your material and obtain a data sheet from the manufacturer, if possible.

« DO NOT RUN SHAPELOCK - it is a very low-temperature plastic not suitable for injection

molding

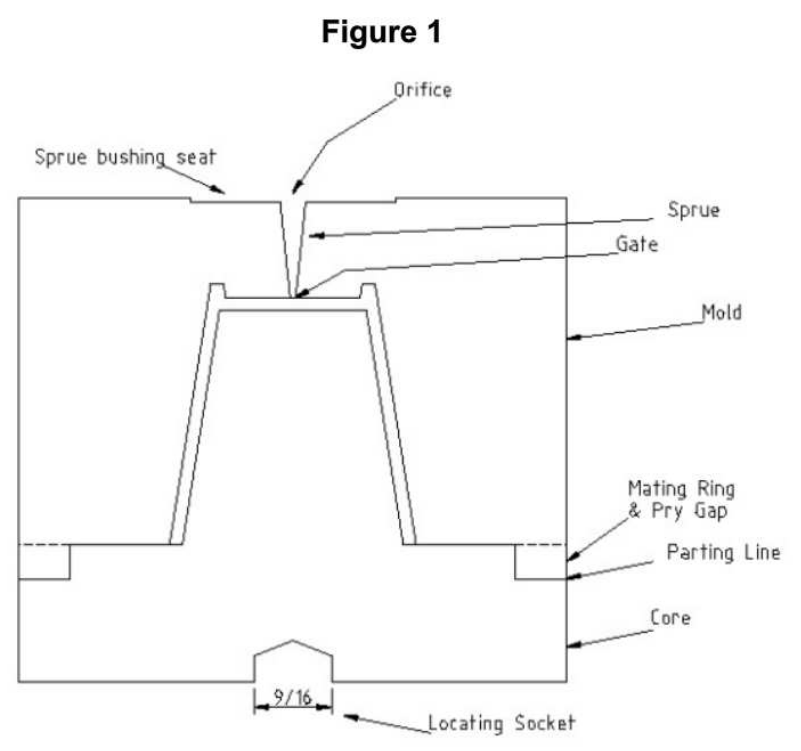

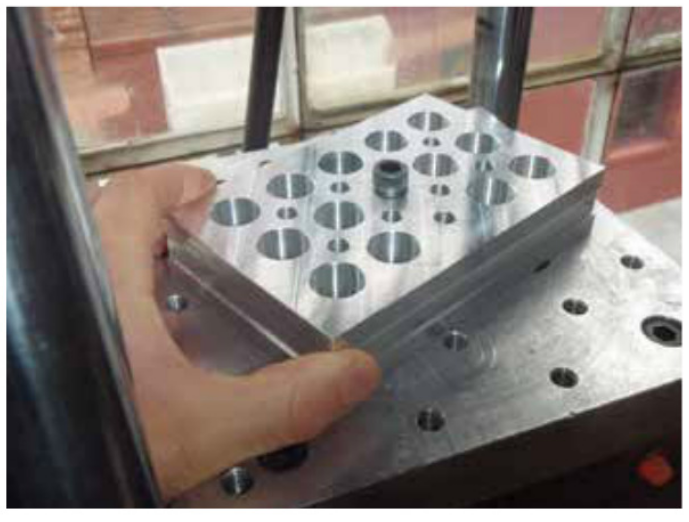

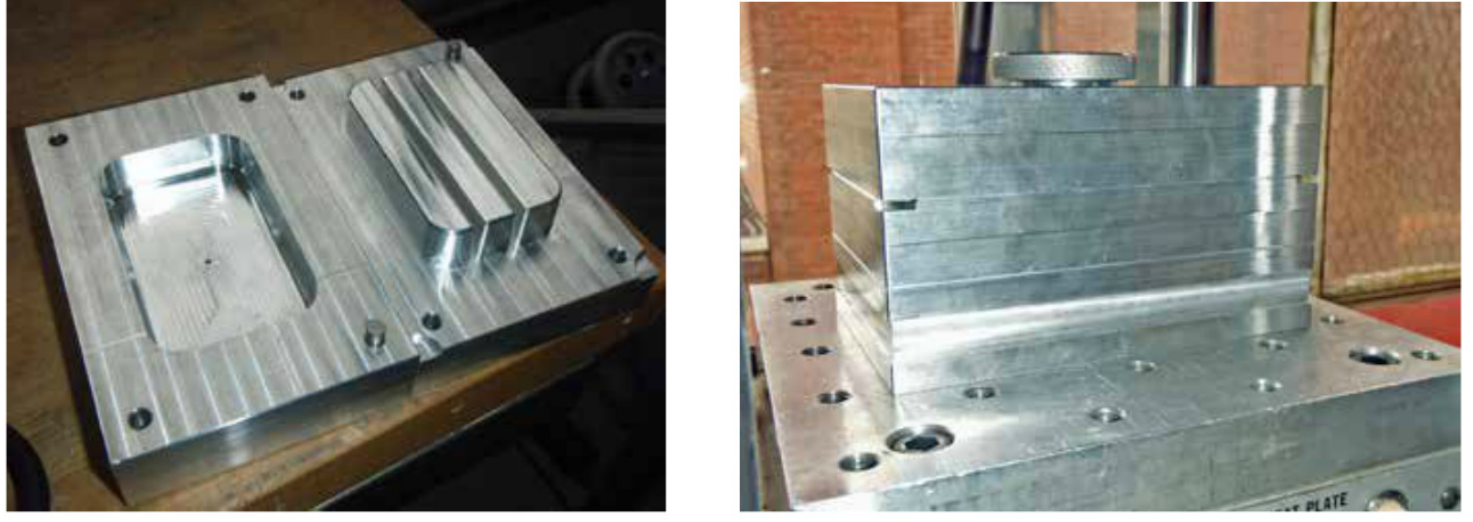

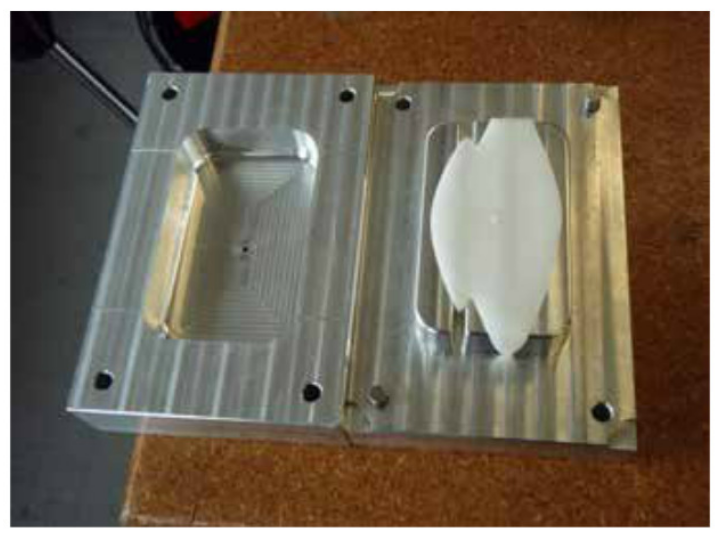

Basic Anatomy of a Mold Figure 1

Qrifice

Making parts with an injection-molding el

machine requires that you bring a mold Sprue bush'“&af //

to use with the machine. There are many

subtleties in mold design, and TechShop

offers a separate mold making class to

dig into those design issues. In this SBU,

we are only going to cover the basic

parts and nomenclature of a mold.

Sprue

-

Gate

Mold

Mating Ring

Figure 1 shows the cross-section of a el

A

ry

Gap

simple two-part manual mold for a cup. " Pactiog Line

fl“‘_’f

CoreBottom Plate

The bottom plate has a locating socket 9/16

that centers the mold over the locating Trlocating Seckst

pin on the mold heater.

The core that forms the interior profile of the work piece is, in this case, part of the bottom plate.

Where the top and bottom plates meet is called the parting line. The top and bottom plates of a mold

need to meet with correct alignment. In this mold, a simple step is turned in the bottom plate that

mates with a ring turned in the top plate.

Top Plate

The top plate molds the exterior profile of the part. The locating ring turned in the top plate is milled

through on each side to provide places to insert tools to pry apart the two parts of the mold. The

injector nozzle on the G-100T is a 1” diameter ball with a 3/16” orifice. This mold is designed to use

a sprue bushing (not shown) between the nozzle and the mold. The sprue carries the melt from the

nozzle to the gate.

Molds should be vented to allow air to escape when material is injected. Vents are typically 0.002”

deep channels milled along the parting line from an edge or corner where air would be trapped. For

the class mold, the vents were machined from the edge of the part to the pry gaps for simplicity.

Other Features

More sophisticated molds have additional features. Runners distribute material from the sprue to the

gates in multi-gate or multi-cavity molds. Core pulls are additional parts of a mold inserted from the

side to create more complex features than a two-piece mold will allow. Ejector pins are used to pop

the part from the mold when the machine unclamps. Inserts are components placed in the mold to

become part of the finished work piece.

Using the Injection Molder

The injection molder requires many steps to set it up. It may seem a little overwhelming at first, but it

will get easier each time you use the machine.

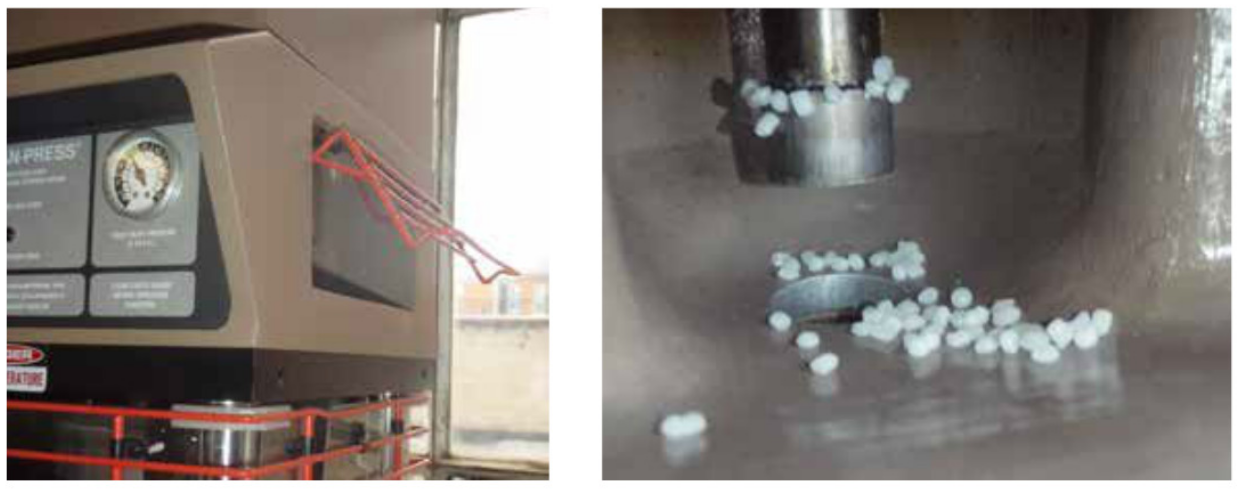

Remove Leftover Plastic and Fill Hopper

Start by checking the hopper for plastic left over from the previous user. If there is plastic in the

hopper, you'll have to heat up the machine up and purge the hopper before adding your own plastic,

which is covered a little later on. If there is no leftover plastic in the hopper, fill the hopper with the

plastic you'll be using.

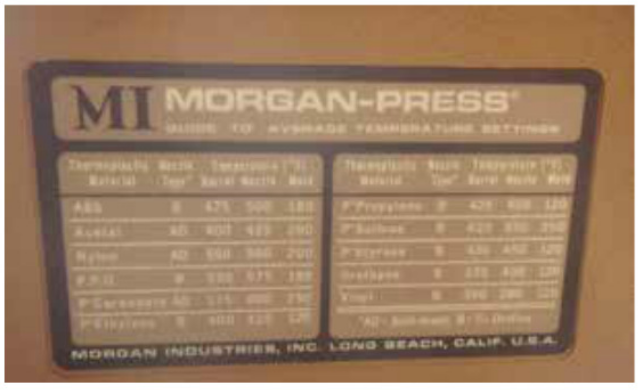

Preheat Injection Molder

1. Turn ON the injection molder by flipping the switch on the side of

the temperature control housing.

2. Adjust the temperatures to match the material you will be

injecting based on the chart on the front of the machine.

3. Begin heating the

heater block to the

correct temperature

MORGAN-PRESS ;

pbtrrsy: <31 s AR e At o e for your plastic. The

e ture tvau mold, injector nozzleMa___w

ev

e

i

___.._f_.:_:.

and

heater take

e e TG about 20 minutes

T LN to heat up, so be careful not to burn yourself on

anything while setting up the rest of the machine.

4. Connect the machine to a shop air

supply, and turn the air on to the

machine using the valve in back.

Underneath the machine are a

booster pump and storage tank.

The booster pump increases the air

pressure to 200 PSI, which is the limit

of the tank. Do not adjust anything

on the booster pump since this could

cause the tank to explode, resulting in

serious injuries or death.

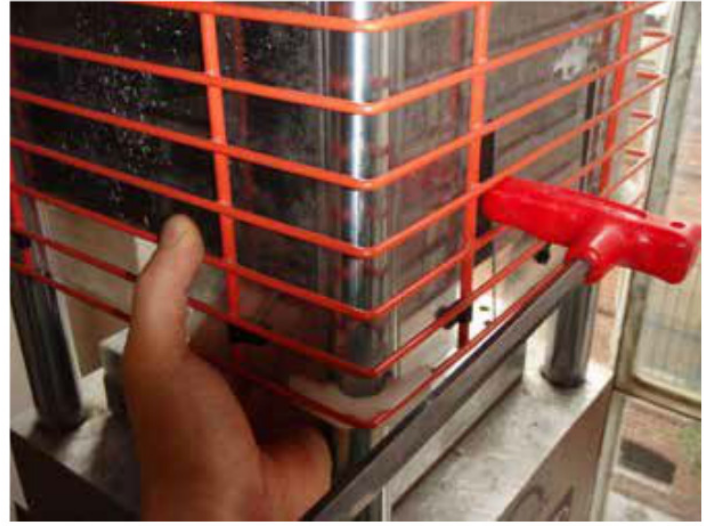

5. Open the material hopper cage. There is a safety device that will not let the machine activate

the plastic injection stroke when the hopper cage is open, which makes the machine much

safer while your hands are inside it and in range of the injection nozzle.

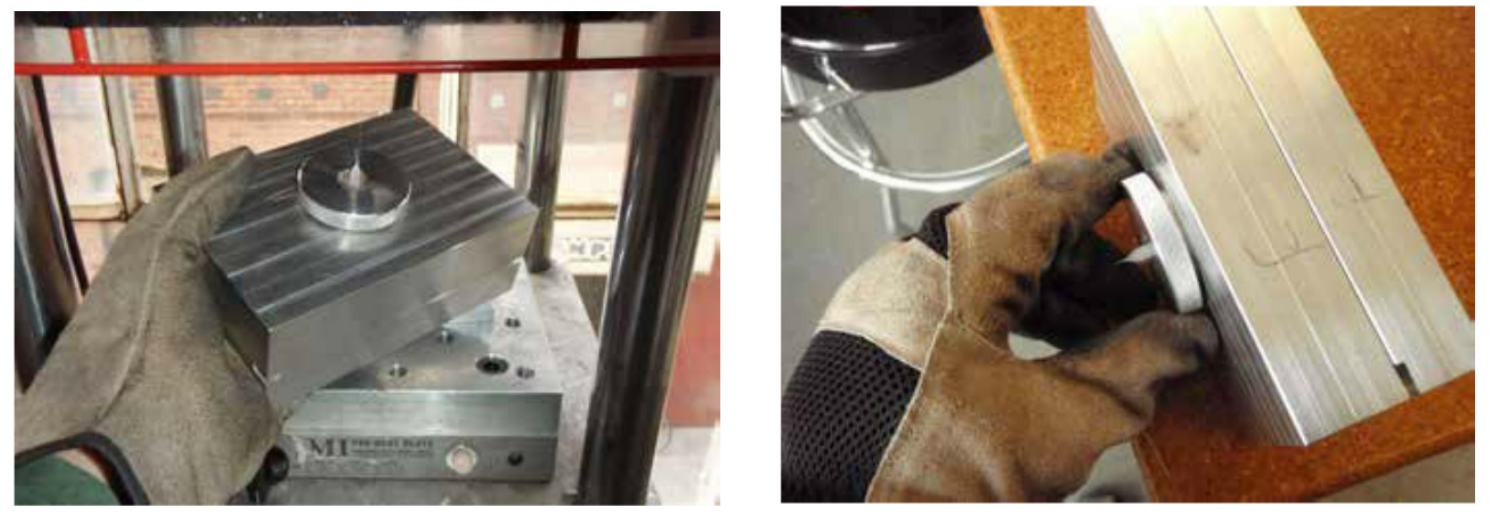

Set Up Mold

1. Insert the locating bolt into the heater block on the bottom platen. The locating bolt keeps your

mold centered under the injection nozzle.

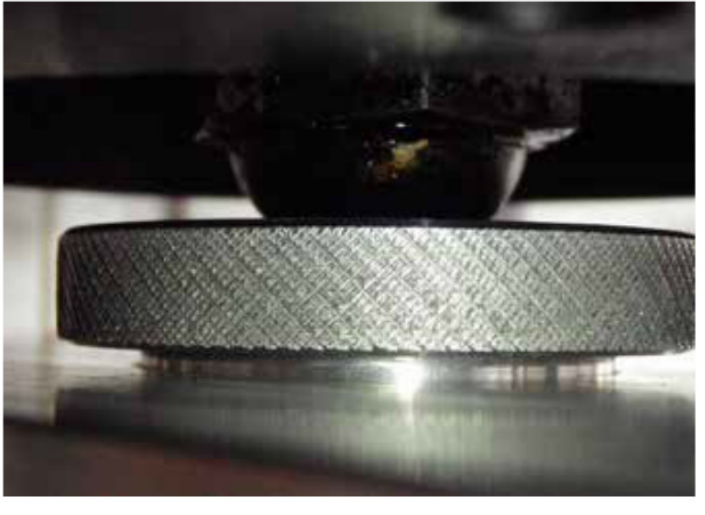

2. Place the riser block onto the locating bolt

and spin it to make sure the locating bolt in

the riser stays centered. Depending on the

height of your mold, you may not need a

riser block. Make sure there isn’t any foreign

material on the riser or heater block surfaces.

The riser block should spin freely about

the locating bolt and should not rock when

applying pressure to one side or the other.

3. Carefully put the two halves of the mold

together. Any scratches inside the mold will

leave marks on your molded parts. Place

the sprue bushing on the top of the mold

and place the mold on the riser block. Check

for any gaps or uneven parts resulting from

misalignment or foreign material on the mold.

4. Adjust the clamp force to 10 tons by

turning the clamp force knob. Ten tons is

the maximum clamping force that may be

placed on the injection nozzle. Depending

on the design and size of your mold, you

may need to use more or less pressure.

5. Adjust the Pilot Pressure to 6.

6. Check to make sure the upper platen is

fully raised. If it is not, loosen the four bolts

holding it in position. Be sure to support the

upper platen when loosening the last bolt,

since it is very heavy. Let the platen fall as

far as it can, then slide the safety cage down

to reveal the backing bolts at each corner

and thread them all the way up into the

machine.

7. Raise the safety cage (it may take quite a bit

of force to engage the catch), then raise the

upper platen as far as it will go and clamp

it in place by

tightening one

bolt.

8. Remove the

mold from the

machine (use

gloves; it will be

warm), lower

the safety cage,

release the

safety on the

clamp knob,

and push itin to

raise the bottomplaten.

9. Raise the safety cage, place the mold and

sprue bushing on the riser block to check

clearances. There should be about 1/4”

between the top of the assembly and the

injection nozzle. If there is not enough

clearance, lower the bottom platen by

turning the adjustment screw on the side of

the machine.

10. Lower the safety cage and pull the clamp

knob out to lower the bottom platen. Place

the mold over the locating bolt on the

riser block. Spin the mold to make sure

it's centered in the machine. Remove any

plastic dripping from the injection nozzle with

needle-nose pliers. Close the safety cage,

release the safety, and push the clamp knob

in to raise the bottom platen.

11. Raise the safety cage and raise the bottom

platen using the adjustment screw on the

side of the machine until the mold contacts

the injection nozzle. Tighten the adjustment

screw further until the mold does not spin on

the riser block.

12. Support the upper platen and loosen the side slide bolt. Do not let the platen fall on the mold.

Place the upper platen on top of the mold and jiggle it to seat it fully on the mold. Tighten the

four side slide bolts to hold the upper platen in place.

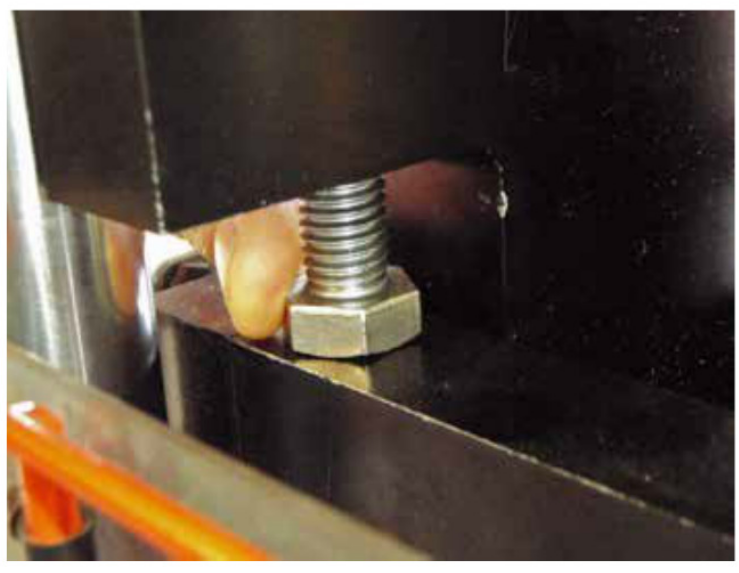

. Lower the safety cage and then lower

the four corner bolts until they are seated

on top of the platen finger tight. (Using a

wrench on the bolts may cause the platen

to become crooked, possibly damaging

the machine or your mold.)

14. Now that the upper platen is in place, it's

time to adjust the clamping force. Lower

the safety cage and pull the clamp knob

out to lower the bottom platen. Adjust your

clamping force to what you’ll be using

while creating parts. Raise the bottom

platen using the adjustment screw on the

side by a 1/4 turn and push the clamp

knob. There will be an audible thump

when the jack screw locks in place at the correct clamping force.

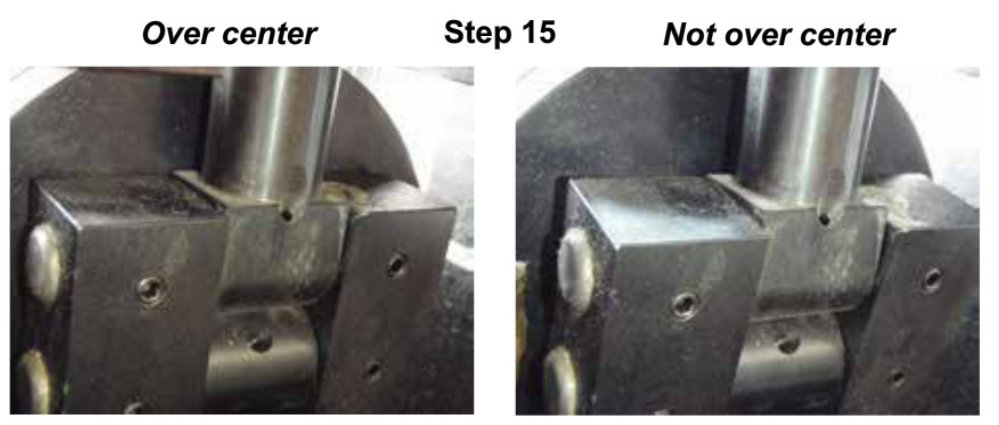

15. If you do not hear a thump while adjusting, check to make sure the jack screw has gone over

center. If it has not, lower the platen adjustment until the jack screw goes over center, and

raise it a 1/4 turn at a time

until you hear the thump. Over center Step 15 Not over center

Clamp and unclamp

the mold a few times to

make sure the thump is

consistent.

Left: The jackscrew is over center,

contacting the pneumatic cylinder

Right: The jack screw is not quite

touching and not capable of holding

the clamping force specified

Set Up Plastic Injection

Now that the mold is set up, you can set up the

plastic injection.

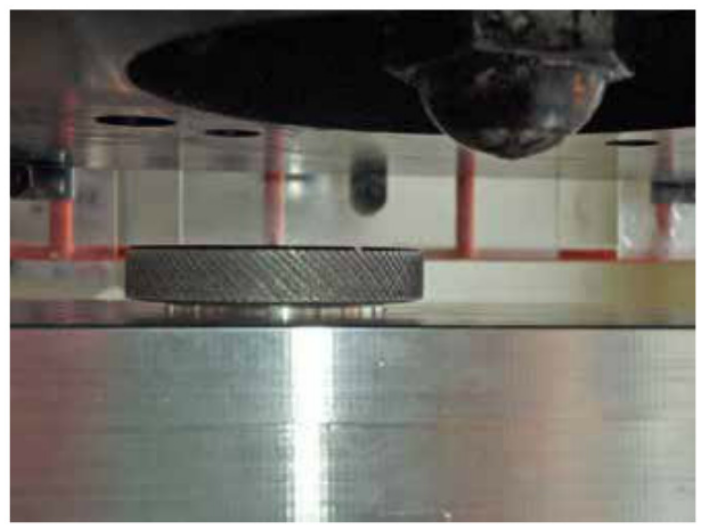

1. Start by adjusting the ram pressure.

Ram pressure controls how fast the ram

moves as well as how much pressure the

plastic being injected puts on the mold.

Figuring out how much pressure to use is a

combination of science, art and experience.

A good starting point is 3000 PSI. Adjust

the pressure using the knob under the ram

pressure gauge.

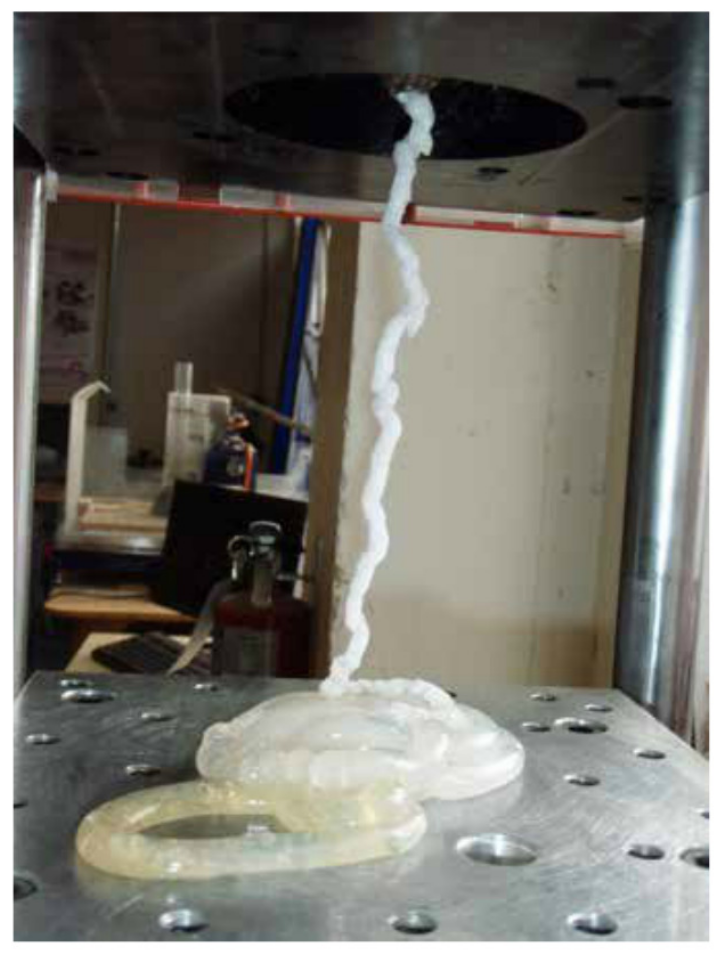

2. Remove the mold and riser plate from the

heater block and lower the safety cage.

Close the hopper cage to enable the plastic

injection stroke. Release the safety and

push the inject knob in. Hot plastic should

come out of the injection nozzle similar to

a hot glue gun. This will help purge any

plastic left over from previous users as well

as any burnt material.

3. Lift the safety cage and clear out the plastic

using a tool (e.g., pliers) instead of your

hands. The plastic will be very hot and

gooey, and may cause severe burns even if

you’re wearing gloves.

4. Place the riser block, mold and sprue bushing

in place over the heater block. Make sure there Step 6

aren’t any gaps between any of the pieces and that

everything is centered on the locating bolts.

5. Lower the safety cage and press the clamp knob to

clamp the mold. Double-check the ram speed gauge,

clamping force gauge and pilot pressure gauge.

6. Turn the small timer knob all the way clockwise until

it stops. Do not apply too much force since it is easy

to break the timer attached to the other side. The

timer comes in handy when making larger quantities

of parts and you know how long the injection cycle

should last.

Make Some Parts

1. Release the safety on the inject knob and push it in

for about five seconds. It should take the mold about

this long to fill and begin to solidify.

2. Release the knob and wait another five seconds.

This keeps pressure on the plastic in the mold and allows the plastic to fully solidify.

3. Pull the clamp knob out to release the bottom platen and raise the safety cage. Carefully

remove the mold using gloved hands. Twist the sprue bushing several times to sever the

plastic holding it to the mold and place it back on the heater block to help keep it warm for

the next part.

4. Carefully split the mold halves apart and pop the molded part out. You may need to use a

screwdriver or other prying implement, but be careful to not damage the mold. You can use

blasts of air or gentle persuasion with a screwdriver to pop the molded piece off the mold.

Do not use too much air since it will cool down the mold.

.

6.

Chances are, the first part will not come

out right. It may take a few tries to get

everything up to temperature and to find

the right injection time, speed and clamping

force. Consult the troubleshooting guide

(located at the back of this handout) and

adjust accordingly.

Keep the hopper full while using the

injection molder. If smoke begins to come

out of the hopper opening, the plastic level

has fallen too far. Depending on the size of

your parts, you may need to add plastic as

frequently as every two or three parts.

Cleanup and Shutdown

1. Scoop out any unused plastic from the hopper. Remove your mold and riser block, lower the

2.

3.

4.

safety cage, and run a few injection cycles

to purge any plastic left over in the hopper.

Loosen the four side slide screws to lower

the upper platen, spin the four corner bolts

all the way in, and lift and secure the upper

platen in its fully raised position.

Lower the bottom platen, turn off the heater

block and lower the safety cage.

Turn OFF the air to the machine. Turn OFF

the machine power, and disconnect the air

supply at the source.

Troubleshooting

Issue

Bottom platen doesn’t move when

the clamp knob is pushed in.

Ram doesn’t operate when you

engage the injection valve.

Lower platen stalls coming down

when disengaged.

Short shots (a short shot is an

insufficiently filled mold).

Cause / Resolution

Is the safety cage all the way down, engaging the safety

interlock?

Is the door to the feed chute closed, engaging the safety

interlock? Is the pilot pressure high enough?

The safety cage should slide smoothly on the stanchions,

but sometimes it sticks. When it sticks, it causes the safety

interlock to trip, cutting off the clamp piston’s air supply. Helping

the cage down by hand is a quick fix. The most likely cause is

contamination of the stanchions by over-sprayed mold release

or other foreign material. Wipe down the stanchions with WD-40

to remove the contamination and lubricate the stanchions.

Resin is too cold, doesn’t flow well because of insufficient

time between shots to fully melt the material, or not gradually

adding material to the barrel on a consistent basis. This is the

most likely cause of short shots in a well-warmed mold. Wait

longer between shots and feed material at a constant rate.

Resin is too cold, doesn’t flow well because cold drool was

injected. Solution: Drool freezes in the air as it comes out of

the nozzle. Don't try to inject it. Use needle nose pliers to pinch

off and discard it. Molds with runner systems can be designed

to divert the leading edge of the flow into a “blind alley” so that

the cold leading edge is parked out of the way.

Resin is too cold, doesn’t flow well because barrel and/or

nozzle temperatures may be too low. Adjust temperatures

judiciously. It is easy to set the temperature too high.

Mold is cold, shot solidifies too quickly. If these are your

first shots, the problem may solve itself after a few shots.

Alternatively, increase temperature of heater block. Note that

using a riser block will reduce the overall efficiency of mold

heating, so you may need to compensate.

Shot time is too short. Use a longer shot.

Shot is too slow. Increase injection speed. Increase injection

pressure. Enlarge gates. Enlarge vents. Enlarge runners and

sprue.

Trapped air. Add and/or enlarge vents.

Issue

Excessive flash (flash is material

that squeezes out of the mold

along the parting line).

Part won't eject.

Plastic doesn’t inject and escapes

from nozzle seat.

Ram won’t return.

Cause / Resolution

Insufficient clamping pressure. Increase clamp pressure.

Reduce injection pressure. Change to a material with lower

viscosity, allowing reduced injection pressure. Increase size of

gates and vents, allowing reduced injection pressure. Redesign

mold to have a smaller area at the parting line. Redesign mold

to include clamping bolts.

Poor platen adjustment. Make sure the top platen is correctly

adjusted square to the mold. Flash only along one side of the

part is an indication of a skewed platen. Make sure the platen is

adjusted to hold the mold securely, and that the adjusting and

suspension screws are tight. If you are using a mold that is too

small to contact the upper platen, redesign the mold to 4"x4” or

larger.

Poor mating at parting line. Re-machine the interface

between the mold plates for a smoother

finish.

Use a squirt of aerosol mold release every few shots.

Eliminate undercuts. Increase taper. Polish mold. Add ejection

mechanism. Remember, plastic shrinks as it cools. It will pull

away from the outside of your mold, and shrink on to the core.

The upper platen is poorly adjusted, creating a gap between

the nozzle and the nozzle seat. Repeat the upper platen

adjustment procedure.

Cold drool fouled the seat and/or blocked the sprue. Remember

to discard cold drool immediately before clamping. Clean

dripping material off the nozzle.

Occasionally, high viscosity or cold material will cause the ram

to get stuck in the barrel. Use short shots on the ram return assist

valve until it breaks free. Each shot should be one second. If it is not

free after 5 or 6 shots, get assistance from a TechShop DC.