Laser Cutter, Rabbit

Manual(s)

Manuals and other reference materials from the manufacturer or other sources.

- Model: Rabbit QX1290

- Manufacturer: Rabbit Laser

- Manual:

- Clearance Required: Rabbit Laser Proficiency Based Clearance

Materials

Approved and prohibited materials for the laser cutters.

Approved Materials for Rabbit Laser Cutters

Scroll up and down to see the list; scroll right for additional information.

Approved Materials for Trotec Laser Cutter

Scroll up and down to see the list; scroll right for additional information.

Prohibited Materials for All Laser Cutters

Unapproved material use is prohibited. Failure to comply will lead to revocation of privileges or membership.

Lasering unapproved material could lead to fire other equipment damage or hazardous fumes creating risk to human health.

Scroll up and down to see the list; scroll right for additional information.

Notes

Know your Poly*

There are many plastic polymers made of different materials. Some can be lasered, others can not. Make sure you think critically about the words that come after poly.

-

Polyacrylic, Polyester, Polyethylene, Polylactic are generally the good ones. See specifics Below

-

Polystyrene requires vigilant observation so you don't burn down the laser.

-

Polyurethane, Polycarbonate, Polypropylene are ones are the bad ones. See specifics Below

Monitor Closely

The following materials MUST BE monitored closely as they have an increased risk to cause damage to the equipment by causing fire or melting.

-

Cotton / Felt / Hemp / Wool (watch for fire)

-

Polystyrene Fire Risk

-

Foamboard/foam core (must not contain fire retardants; R.L. Adams is known good) HIGH FIRE RISK the entire job must be monitored closely.

-

Coroplast brand corrugated polypropylene watch for melting; bulk polypropylene is not approved)

Etched Only

-

Glass

-

Ceramic

-

Stone (marble, slate, quartz, etc.)

-

Plaster of Paris

-

Paints and thin spray coatings, thinner than powder coating (General blanket approval, but please use common sense and don't engrave your grandfather's old High Lead Special paint he has stockpiled.

-

Metal (painted/anodized)

-

The laser must not be used over 50% power in this scenario. Reflections can damage the optics.

Submission of Material For Consideration

To submit a material for approval submit the request to the #lasers channel on Discord. Please provide the Safety Data Sheet (SDS).

Laser Material Spreadsheet

The source of the above tables can be found in the following Google Sheet:

https://docs.google.com/spreadsheets/d/1RDp_Kf5wWVkaAUypppxwd_1NlgEtOxAvZAGb8n5b-Vc/edit?usp=sharing

The Google Sheet has several pages, including:

- Notes on the spreadsheet

- Approved materials for the Rabbits, including suggested speed and power settings

- Approved materials for the Trotec, including suggested speed, power, and resolution settings

- Prohibited materials (applicable to all laser cutters)

Member Notes

Resources

Where to obtain materials, consumables, and tooling.

Lightburn Basic Features Walk-through

Lightburn Cut Settings

Lightburn Support Forum

Inkscape: The Basics

Inkscape: Hand Trace Images

Inkscape: Auto-trace images into vectors

Corel Draw: Anatomy of Vectors

Corel Draw: Vector Tracing Tutorial

Corel Draw: Envelope & Perspective Tool

Adobe Illustrator in 5 minutes

Adobe Illustrator: Turn Images into Vectors

Adobe Illustrator Pen Tool Tips

Adobe Illustrator: Turn Type into Shapes

Acrylic Purchasing Guide - Made by Morgan Swartz

Tool Tutorial

Class Handout

The class handout for basic laser operation: laser_101-basic_operation.pdf

Old Tutorial (Possibly Out of Date)

A laser cutter is used to mark, engrave, or cut a wide variety of materials. They work a lot like printers do, where you send a graphic to print. Instead of ink, the laser uses heat to transfer the image onto the material.

Do not use prohibited materials in the laser (see Material Safety for allowed and prohibited materials)

Stay by the laser while it is running!

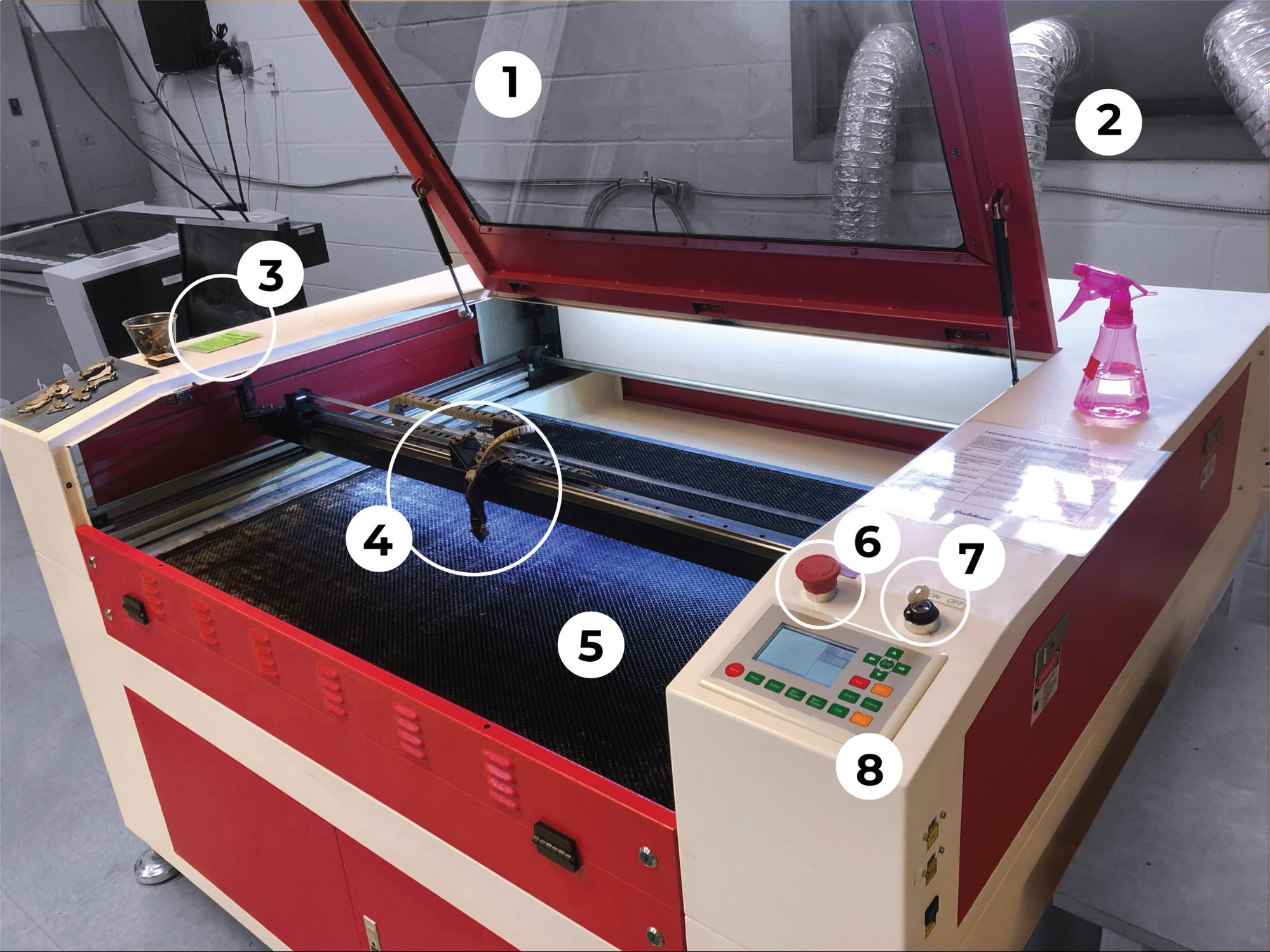

Tool Anatomy

-

Lid - Absorbs the laser radiation and must be closed when running a job

-

Exhaust - Allows for the efficient removal of fumes and particulate

-

Maintenance Tag - Manually tracks the usability status with Green/Yellow/Red cards

-

Lens Carriage - Houses the mirror, lens, and air assist

-

Cutting Bed - 1200 x 900mm (~47” x 35”) Consists of a removable, magnetic honeycomb tray. Seated properly, it should feel stable & secure

-

Emergency Stop - Reserved for emergencies. To deactivate and reset, you must twist the spring-loaded knob.

-

Power Switch - Key switch turns the machine on and off

-

Control Panel - LCD interface with commands to operate the laser

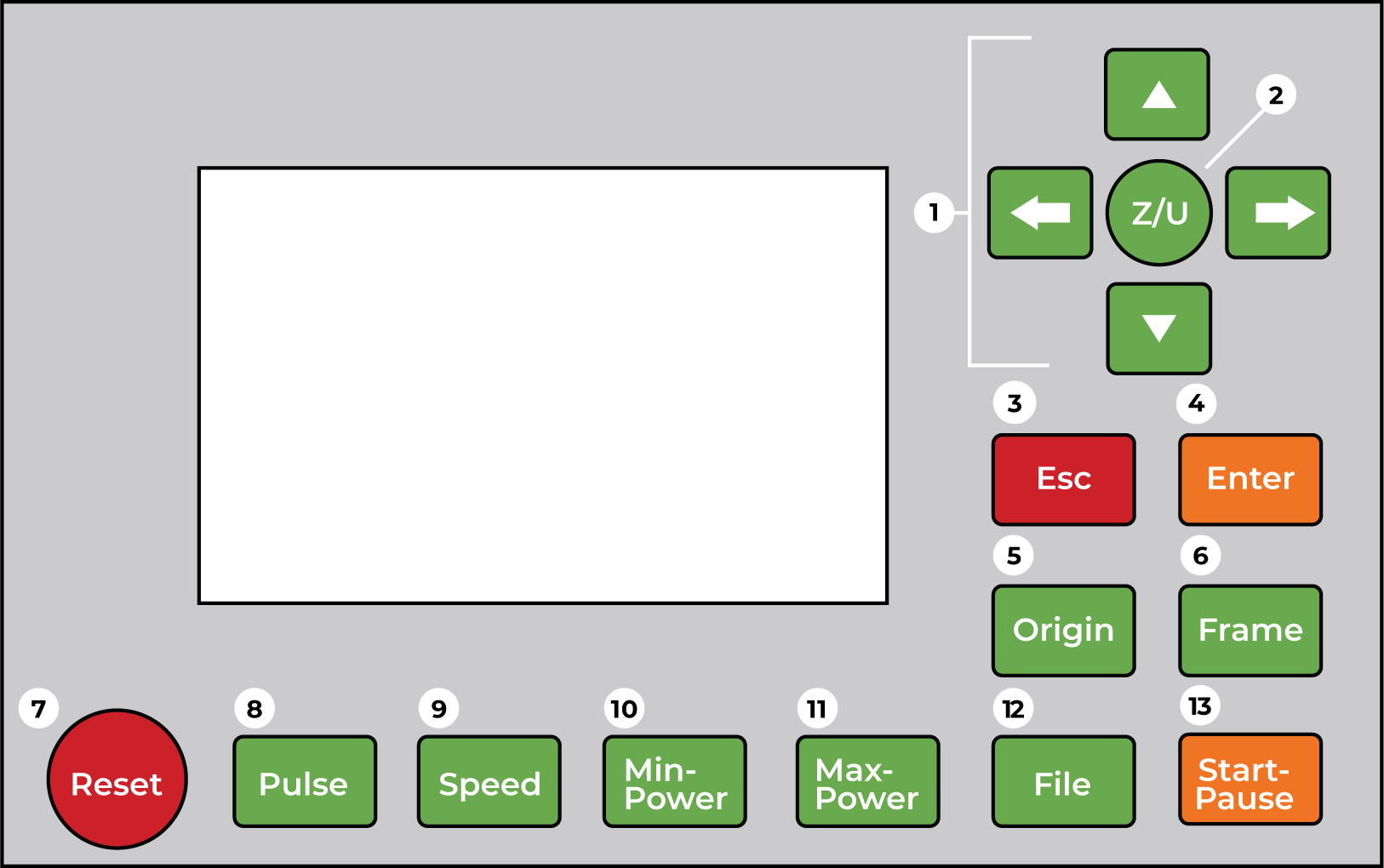

Control Panel

-

Jog X-axis and Y-axis

-

Adjust Z-Axis

-

Exit Menu/Return to main screen

-

Select menu item

-

Set Job Origin

-

Trace the footprint of a job to check its size and placement

-

Reset machine, Abort Job

-

Pulse the laser to mark its precise location

-

Adjust speed (mm/sec)

-

Adjust power (0-100%) for the areas the laser approaches a node/edge

-

Adjust power (0-100%) for the areas where the laser is mid-cut/mid line

-

Retrieve file sent to the machine (job queue)

-

Start job, pause job, resume job

Tool Safety

Common Hazards

| Fire | Toxic Fumes | Lens Collision |

|---|---|---|

| Listen for the exhaust. It should automatically turn on with the laser. | Be mindful of the safety of your cutting material. | Load material with care. |

| Vacuum beneath the cutting bed to prevent flammable build-up. | Avoid chlorinated plastics and other prohibited material on the list. | Be mindful when moving the cutting bed to vacuum. |

| Avoid foam and other prohibited material. | Off-gassing dangerous fumes like chlorine and cyanide is always a concern. | Ensure material is flat and will not collide with the lens carriage during operation. |

Always pause the laser if you need to step away from the machine!

Prohibited Materials

Do not use prohibited materials in the laser (see Material Safety for allowed and prohibited materials)

Inspection

Before you start using the tool you are expected to do an initial inspection and assess its readiness for use.

Setup

RASTER VS. VECTOR Rastered data is an image that is made of pixels. Much like an inkjet printer, the laser will scan the artwork on a scale from black to white. The laser will vary the number of dots it fires depending on the tone of each pixel.

Common file formats like .jpeg, .gif, and .png are all rastered data.

Vectored data is made of paths that form lines and shapes. They contain mathematical data that allows the laser to trace the path like following coordinates on a map. This allows the laser to cut or score a line as well as etch a filled shape.

Common file formats like .ai, .dxf, and .svg are all vectored data.

-

Power on the laser

-

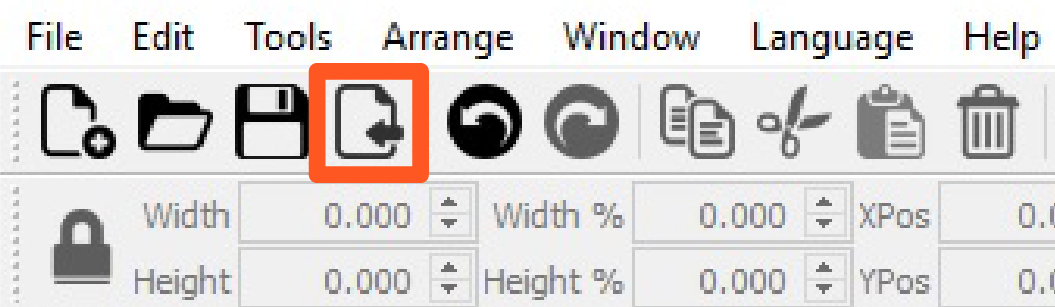

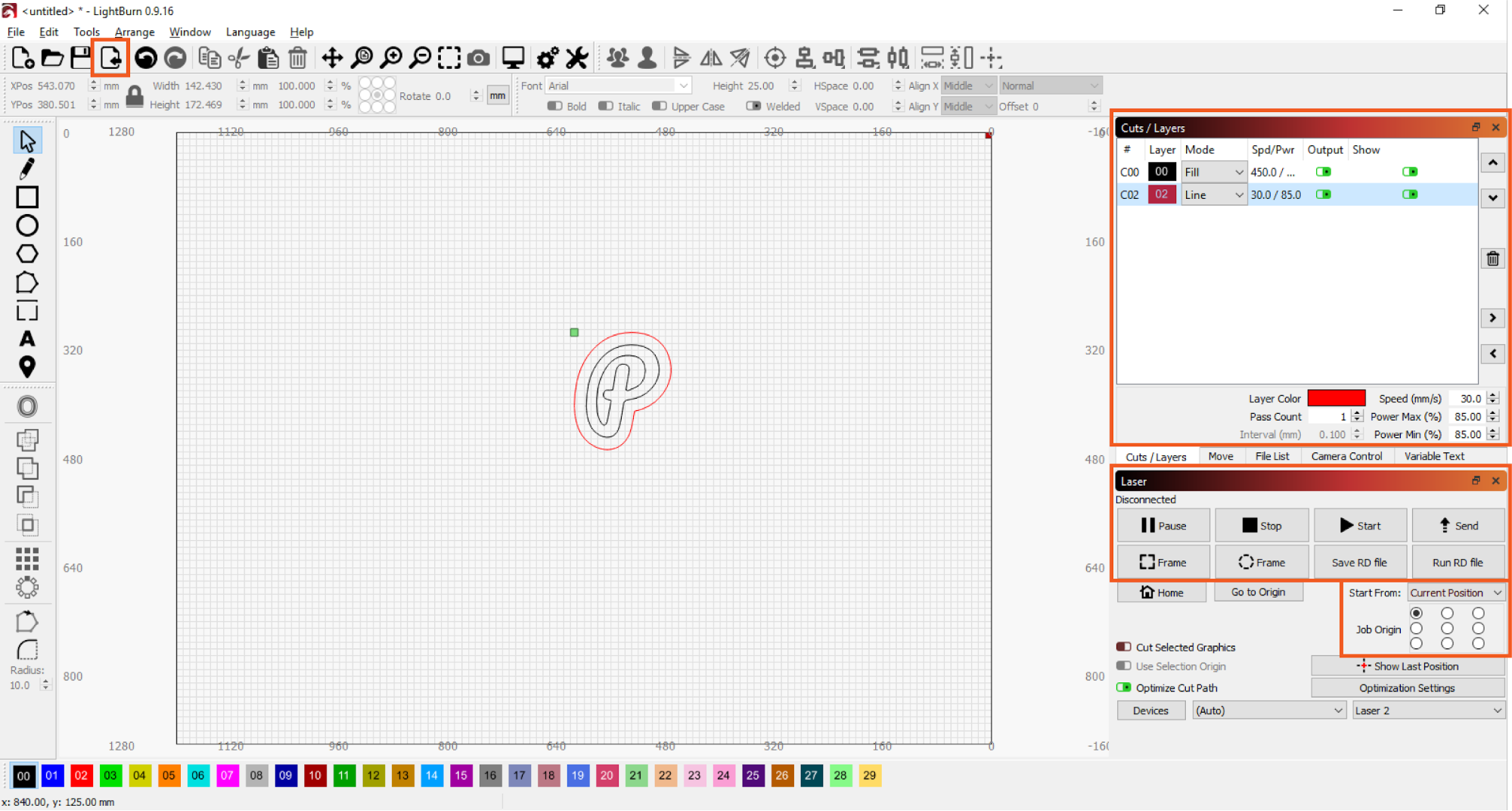

Import your file into Lightburn

-

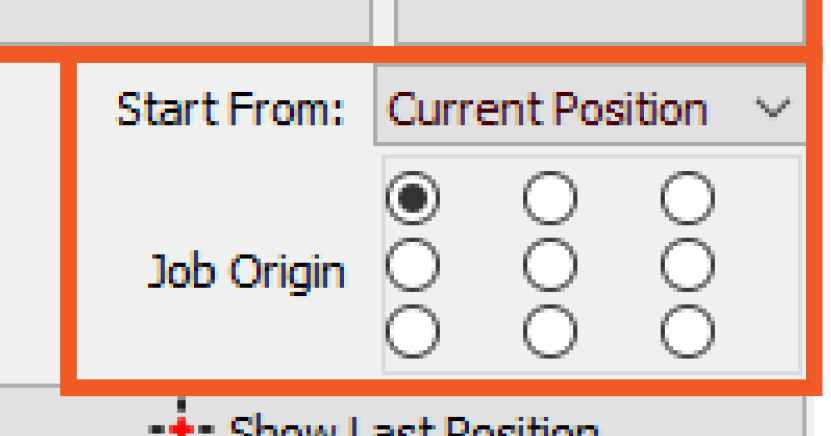

Set the job origin in Lightburn

-

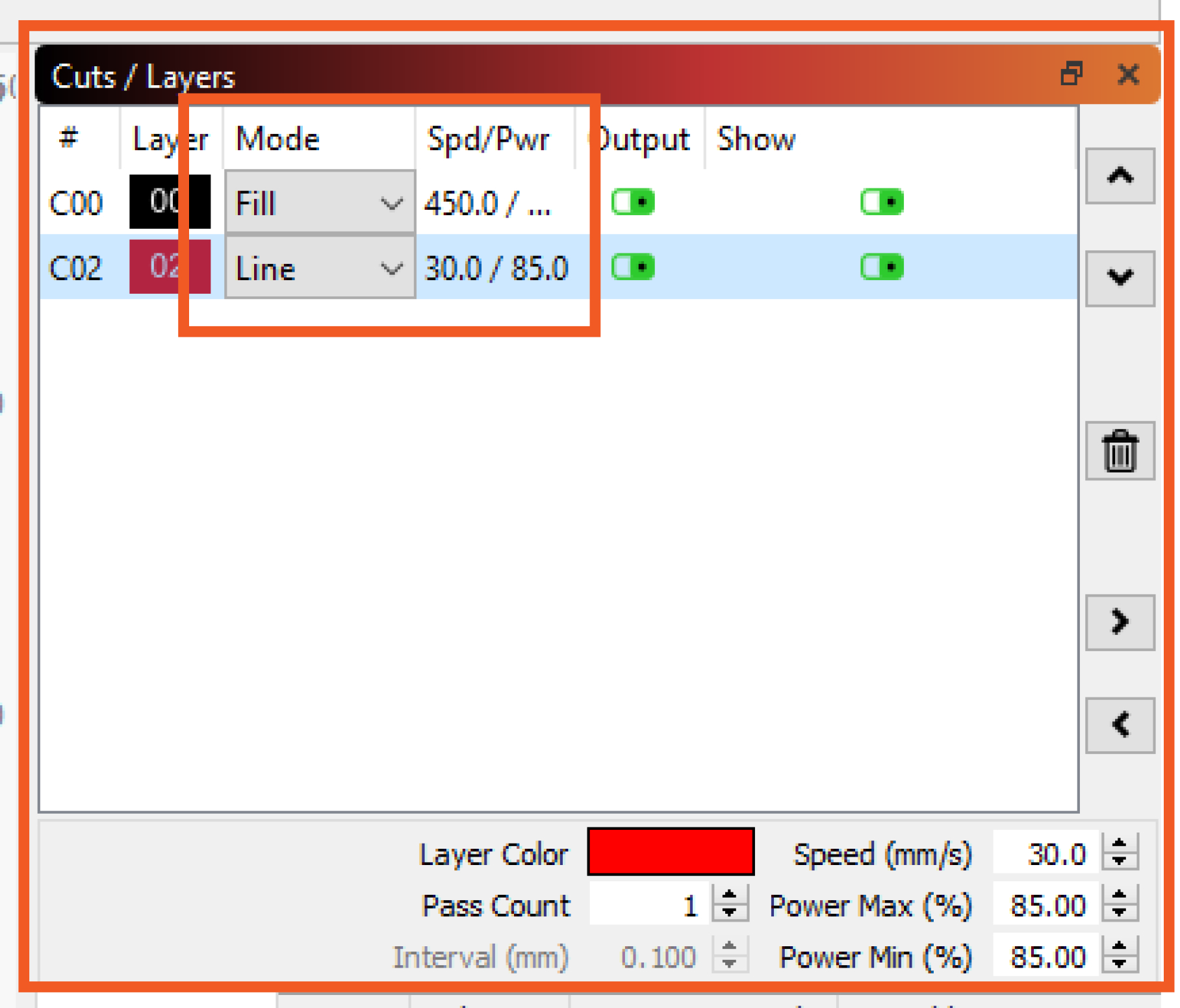

Check the layer mode

-

Adjust the speed and power settings

-

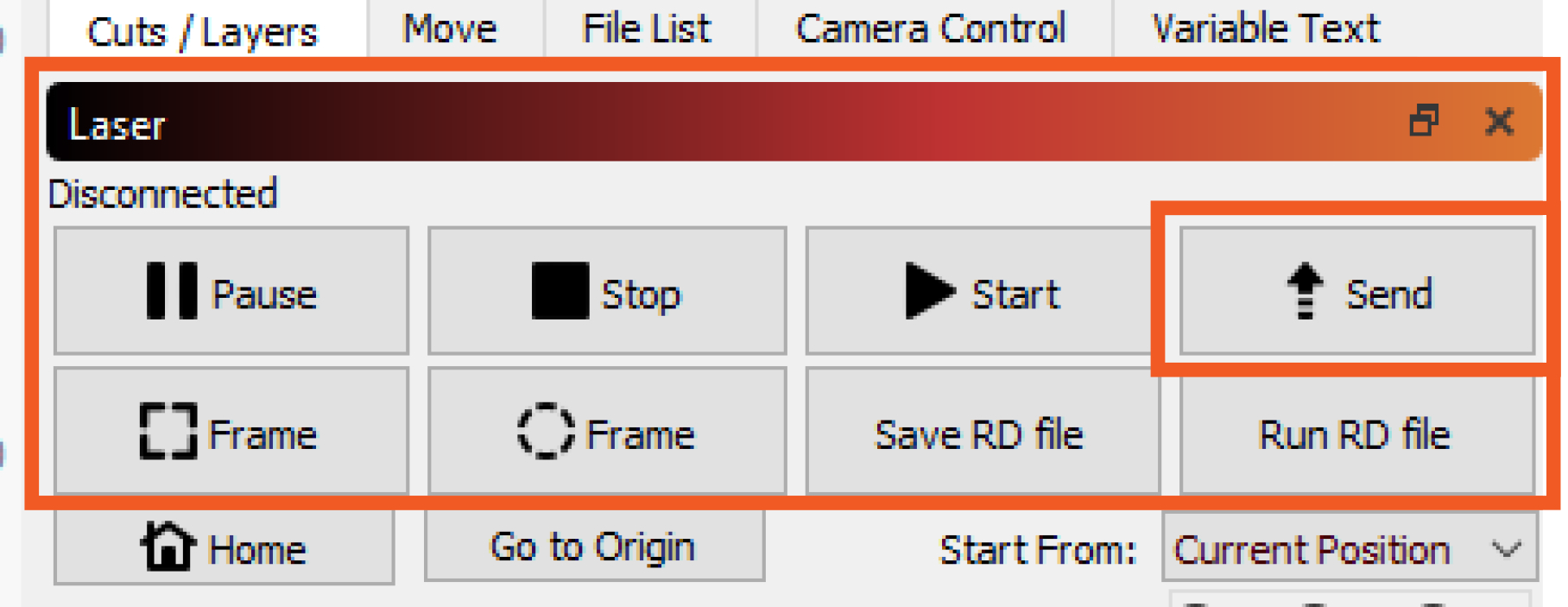

Send your file to the Laser

Lightburn Setup

Lightburn accepts a range of file formats.

Lightburn accepts a range of file formats.

Supported vector files: .ai .pdf .dxf .svg .lbrn

Supported image files: .jpg .jpeg .png .tif .tiff .bmp

-

-

fill—fills a vector shape to etch

-

line—traces along a vector line

-

images—will only etch and optimize for a rastered photo

-

-

Adjust the speed and power settings.

Common Cut Settings

| Material | Thickness | Power(%) | Speed (mm/s) |

|---|---|---|---|

| Bass Wood | 1/8“ | 50 | 15 |

| Balsa Wood | 1/8” | 50 | 45 |

| Birch Plywood | 3/16” | 70 | 10 |

| Acrylic | 1/4“ | 55 | 12 |

| Leather | 1/16” | 70 | 12 |

Common Cut Settings

| Material | Thickness | Power(%) | DPI |

|---|---|---|---|

| Acrylic | 55 | 300 | 391 |

| Anodized Aluminum | 25 | 325 | 391 |

| Cermark | 50 | 300 | 362 |

| Granite | 85 | 150 | 299 |

| Glass | 12 | 350 | 462 |

| Leather | 45 | 325 | 299 |

| Powder Coated Metal | 25 | 325 | 299 |

| Romark | 12 | 325 | 254 |

| Wood | 14 | 350 | 300 |

Operation

-

Listen for the exhaust to ensure that it is on

-

Check that your material is safe to cut

-

Load material

-

Focus the lens on your material

-

Set the origin on the laser

-

Check the footprint of your job

-

Start your file

-

Monitor the machine until the job is complete and cleanup

Focusing the Lens

-

Select Z (Control Panel 2) to change to bed height control.

-

Use ↔ (Control Panel 1) to align the lens carriage to the focus gauge (Right raises bed, left lowers)

-

Select Esc (Control Panel 3) to return to the main menu.

Setting the Origin

-

Use the directional arrows (Control Panel 2) to jog the lens carriage to the desired location.

-

Optional: Press Pulse (Control Panel 8) to verify the exact location.

-

Select Origin (Control Panel 5) to set the Origin

-

Select Frame (Control Panel 6) to check the footprint of job. (framing can also be managed from Lightburn control)

Cleanup

-

Power off the Laser

-

Reset any modified computer settings to default

-

Vacuum the interior so material does not build up beneath the honeycomb

-

Note any maintenance needs or concerns on the tag and at protohaven.org/maintenance

-

Recycle waste in the single-stream scrap bins

-

Empty the bin when full

Scrap Breakdown

There are two black scrap bins reserved for laser waste. Maintaining these is a shared, communal responsibility.

When you notice the scrap bins are full, it’s time to take it to the dumpster out back. Feel free to enlist a helping hand.

If you notice valuable material while emptying the bins, use your judgement to selectively save a few pieces or take it home for your personal use.

Troubleshooting

| Problem | Likely Cause | Potential Solution | |

|---|---|---|---|

| Cut does not go through the material | The speed is too fast or the power is too low | Use a scrap piece of the same material to make a series of tests with incremental adjustments until you find the sweet spot | |

| The lens or mirror is fogged | Alert the staff or volunteer on duty to the issue | ||

| Slop in the frame | The origin in Lightburn is not set appropriately | Adjust the origin point in Lightburn | |

| The artwork is too large for the cutting bed: 1200 x 900mm (~47 x 35”) | Adjust the overall artwork size | ||

| Burn marks on the back of the material | Hot debris is scorching the edges of the cut lines | Lay a sheet of paper beneath the material and the bed or line it with a laser-safe vinyl free tape | |

| No visible cutting happening | Lid safety switches not engaged, or software issue | Confirm the lid safety switches click when the lid closes. Turning the machine off and on again may also help if that isn't the problem. |

Special Setups

-

Register your material on the cutting bed using magnets or tape when doing a production run.

-

Use the front pass-through door for extra long pieces.

-

Use surface treatments like Cermark or paint to etch designs onto metal surfaces.